In industrial fluid systems, hot water is often more challenging than it appears. Elevated temperature accelerates material aging, causes softening, and increases the risk of contamination. For this reason, many engineers and buyers prefer PP Polypropylene Tube when designing pipelines for hot water transfer. Its performance advantage is not accidental—it is rooted in polypropylene’s molecular structure and crystallization behavior, which allow it to remain stable where other plastics struggle.

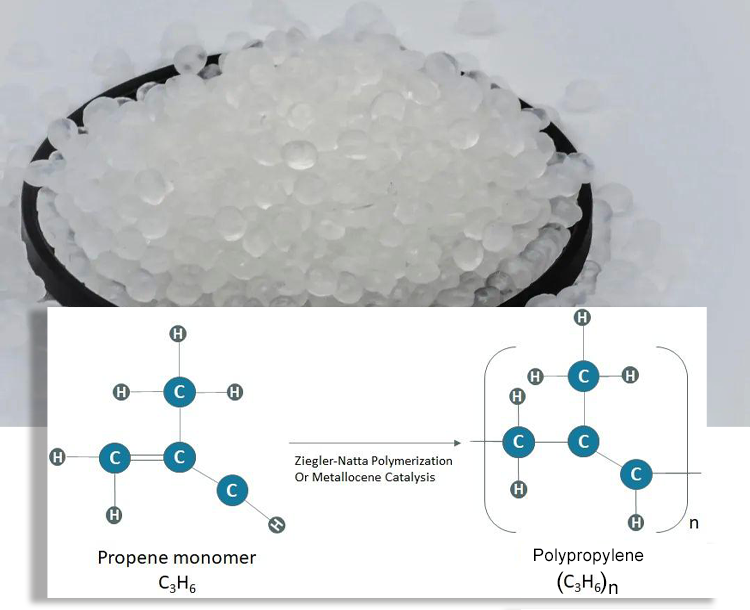

Molecular Structure Explains Heat Resistance

Polypropylene belongs to the polyolefin pipe family, characterized by a semi-crystalline molecular structure. This structure gives PP tubing a higher melting point and better thermal stability than many amorphous plastics.

When exposed to hot water, PP Polypropylene Tube maintains its shape and mechanical strength, rather than softening or deforming. Unlike materials that rely on plasticizers, PP’s stability comes from its polymer backbone, which remains intact under heat.

This inherent stability is critical in continuous hot water circulation systems.

Crystallinity and Dimensional Stability in Hot Water

The crystallinity of polypropylene pipes plays a major role in dimensional control. Higher crystallinity means molecular chains are packed more tightly, reducing movement under thermal stress.

In practical terms, this allows PP tubing to resist expansion, wall thinning, and deformation during prolonged exposure to hot water. Dimensional stability reduces joint stress, which is especially important in welded piping systems and fixed installations.

Why PP Does Not Leach or React in Hot Water

Hot water accelerates chemical interactions in many plastics. Some materials release additives or react with process fluids over time. PP Polypropylene Tube is chemically inert, meaning it does not leach harmful substances even at elevated temperatures.

This property makes PP tubing suitable for applications where water purity matters, such as cleaning systems and process water lines. It also helps systems meet hygiene and safety expectations without complex material certification.

Performance Comparison: PP vs. PVC and PU in Hot Water

Different plastics behave very differently under heat. The table below highlights why engineers often avoid PVC and PU for hot water transfer:

| Material | Hot water performance | Typical limitation |

|---|---|---|

| PP Polypropylene Tube | Stable, no softening, inert | Requires proper welding |

| PVC | Softens, plasticizer migration | Limited temperature range |

| PU tubing | Loses elasticity, ages quickly | Not suitable for continuous heat |

This comparison shows why polypropylene pipes are preferred in systems where hot water is present for long periods rather than intermittently.

Advantages in Chemical Cleaning and CIP Systems

Chemical processing and food industries frequently use hot water in cleaning-in-place (CIP) systems. These processes combine high temperature with cleaning chemicals, creating a harsh environment for piping.

PP Polypropylene Tube performs well under repeated hot water flushing, maintaining structural integrity and chemical resistance. Its smooth inner wall also reduces residue buildup, supporting effective cleaning cycles. For engineers, this means fewer maintenance interventions and longer service life.

Mechanical Strength Under Thermal Cycling

Hot water systems rarely operate at constant temperature. Thermal cycling—heating and cooling repeatedly—can fatigue materials. Polypropylene tubing absorbs thermal stress without cracking, thanks to its balance of stiffness and flexibility.

This makes PP tubing suitable for industrial plants where systems are frequently started and stopped. Reliable performance under thermal cycling is a key reason PP is widely specified in utility and process piping.

Cost and Availability Benefits for Buyers

From a procurement perspective, PP Polypropylene Tube offers a strong cost-performance ratio.

Compared with high-end fluoropolymers, PP provides sufficient heat resistance for hot water applications at a significantly lower cost.

For distributors and end users, this means easier inventory management and broader application coverage.

PP tubing often meets technical requirements without exceeding budget constraints.

(FK9026)