When a high-speed cylinder fails to reach its designed cycle time, engineers often blame the valve or air supply. In reality, the hidden restriction is frequently the Mini Push In Fittings installed at the cylinder port. A small bore air fitting with limited internal diameter can create unexpected back pressure, leading to a clear pneumatic speed issue in precision automation systems.

For equipment engineers and distributors serving fast-cycle machinery, understanding how fitting bore size influences cylinder response is critical to improving productivity without redesigning the entire pneumatic circuit.

Why Mini Push In Fittings Affect Cylinder Response Time

High-speed cylinders depend on rapid air filling and exhausting. When mini push in fittings have a narrow effective orifice, they act as throttling points. Even if the supply pressure is stable at 0.6–0.8 MPa, restricted flow reduces actual chamber pressure build-up rate.

In small-bore cylinders (Ø12–Ø25 mm), the airflow volume per stroke is limited, so any additional restriction proportionally increases cycle delay. A standard brass push in fitting with a 2.5 mm internal bore may reduce airflow by over 20% compared to a 4.0 mm design under identical pressure conditions.

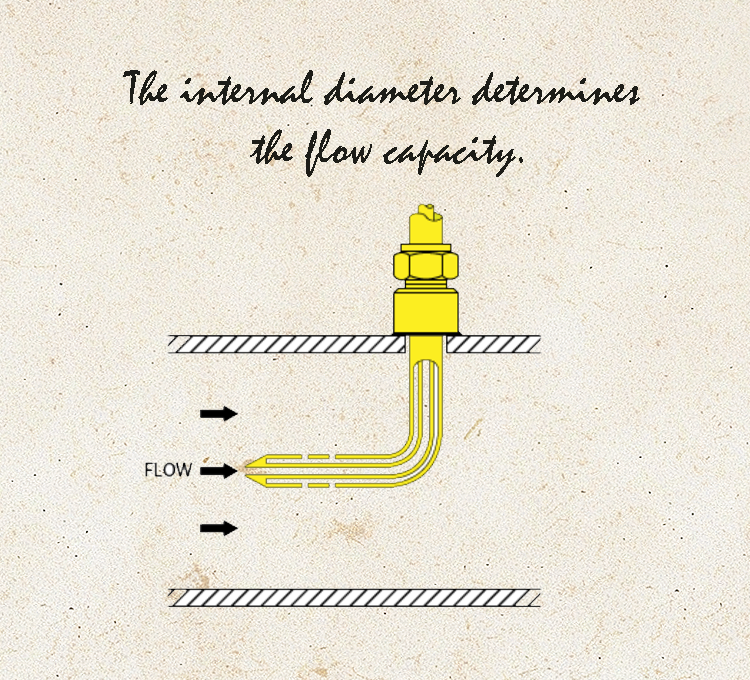

The fitting bore, not the thread size, determines real flow capacity.

For engineers selecting compact components, reviewing the effective flow diameter instead of only the thread specification is essential.

Comparing Effective Bore of Small Bore Air Fitting Options

Thread size (M5, 1/8”) does not guarantee equal performance. Below is a simplified comparison based on internal structure testing from industry benchmarks:

| Fitting Type | Thread | Effective Bore (mm) | Relative Flow Capacity |

|---|

| Standard brass push in fitting | M5 | 2.5 | 100% |

| Compact mini air connector | M5 | 3.2 | 135% |

| High flow mini fitting | M5 | 4.0 | 180% |

Data based on internal airflow testing and pneumatic performance comparison.

Even with identical outer dimensions, optimized internal channels and shorter flow paths significantly reduce pressure drop. For distributors, offering a high flow mini fitting series provides measurable value to customers operating packaging lines, pick-and-place systems, or labeling machines.

Brass Push In Fitting vs. High Flow Mini Design

Material alone does not solve airflow restriction, but structural design does. A traditional brass push in fitting often prioritizes durability and cost control. However, internal geometry may include sharp transitions that increase turbulence.

A redesigned mini air connector typically features:

◆Streamlined internal air channel

◆Reduced sealing lip obstruction

◆arger effective bore within the same outer size

◆Improved exhaust efficiency

For high-cycle applications exceeding 60 cycles per minute, minimizing micro-restrictions reduces cumulative energy loss and improves stroke consistency. This is especially important when paired with responsive pneumatic solenoid valves, where airflow bottlenecks negate valve performance advantages.

Identifying a Pneumatic Speed Issue in the Field

A pneumatic speed issue caused by small bore air fitting restriction often presents as:

◆Cylinder extends quickly but retracts slowly

◆Inconsistent stroke time under load

◆Increased exhaust noise

◆Higher-than-expected air consumption

Instead of increasing pressure, engineers should first inspect connector bore size. In one automated sorting system upgrade, replacing standard mini push in fittings with high-flow models reduced cycle time by 12% without modifying the valve or cylinder.

This type of improvement directly impacts throughput and return on investment for factory managers.

Selecting the Right Mini Push In Fittings for High-Speed Systems

When specifying fittings for compact automation, consider the following:

1.Match fitting bore to cylinder port size

2.Verify actual effective diameter, not just thread type

3.Check flow rate specifications under 0.6 MPa conditions

4.Ensure compatibility with pneumatic air filters and supply tubing

For distributors and procurement managers, stocking both standard and high flow mini fitting series allows flexible solutions across different machinery requirements.

In high-speed automation, small components determine big performance differences. Choosing the right Mini Push In Fittings is often the simplest and most cost-effective way to unlock faster, more stable cylinder motion—without redesigning the entire pneumatic system.

(FK9026)

Polyurethane Pneumatic Tubing Hardness Combination Strategy for Multi-Station Automation Lines

Polyurethane Pneumatic Tubing Hardness Combination Strategy for Multi-Station Automation Lines

Mini Push In Fittings and High-Speed Cylinders: Solving the Flow Bottleneck

Mini Push In Fittings and High-Speed Cylinders: Solving the Flow Bottleneck

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems