Jan 26, 2026

In daily maintenance of pneumatic systems, many engineers encounter a frustrating problem: SMC Pneumatic One Touch Fittings that were once easy to disconnect become increasingly difficult to release. This is not a coincidence or a sign of “better holding power.” In most cases, it indicates internal wear or material change that should not be ignored. Understanding why a Pneumatic Push-in Fitting tightens over time helps engineers and purchasing teams decide when replacement is safer than forcing continued use.

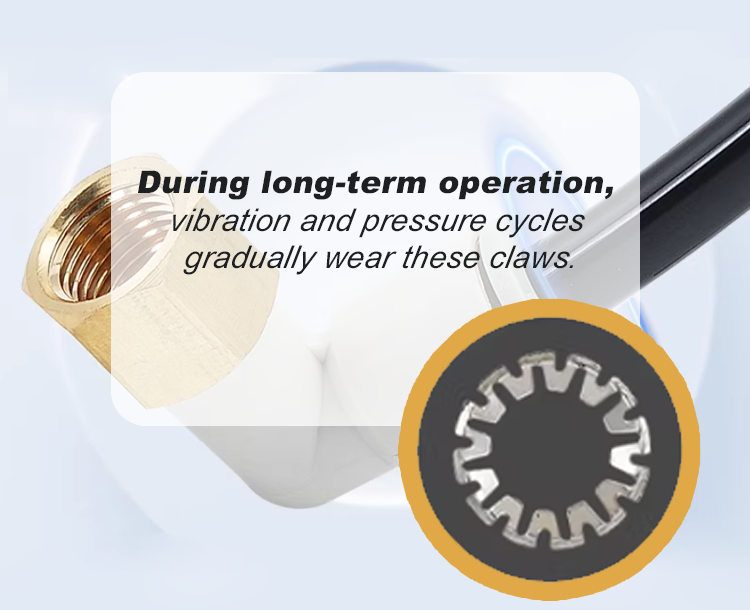

Inside every one touch fitting, stainless steel claws grip the tube while allowing quick release. During long-term operation, vibration and pressure cycles gradually wear these claws. Instead of gripping evenly, worn claws dig into the tube surface at irregular angles.

This uneven contact increases resistance during tube removal, misleading technicians into thinking the fitting is still reliable. In reality, claw wear is often the earliest sign that a fitting is approaching the end of its service life.

Not all problems come from the fitting itself. Soft tube materials such as PU or nylon deform under constant pressure and temperature fluctuation. When used with Pneumatic fittings for extended periods, the tube end may become permanently indented by the claws.

Once deformed, the tube locks into the fitting body and resists release. Reusing such tubing significantly increases leakage risk, even if the fitting appears intact.

Compressed air systems are rarely free from contaminants. Fine dust, oil mist, and metal particles can enter the fitting during tube replacement or routine maintenance. Over time, debris accumulates around the collet spring.

In SMC Pneumatic One Touch Fittings, this contamination restricts collet movement, preventing full release. Increased tightness caused by contamination cannot be fixed by force—it requires replacement and improved air filtration upstream.

(See related guide: Air Preparation Units for Pneumatic Systems)

In high-speed automation lines, pressure does not rise and fall smoothly. Sudden pressure spikes create micro-impacts between the tube and claw. With repeated cycles, the tube surface hardens locally.

This phenomenon is common in systems using Pneumatic Quick Coupling solutions under unstable regulation. The fitting may still hold pressure, but removal force increases sharply, signaling material fatigue rather than strength.

A common mistake in factories is judging fittings only by whether they leak. A Pneumatic Push in Fitting that grips too tightly often has compromised sealing geometry. After tube reinsertion, micro-leaks may appear hours or days later.

For distributors and procurement managers, explaining that fittings are consumable components—not permanent fixtures—helps reduce downtime and warranty claims.

The table below helps identify whether replacement is the correct action:

| Observed condition | Likely cause | Recommended action |

|---|---|---|

| Tube hard to remove, no visible damage | Internal claw wear | Replace fitting |

| Tube end deeply indented | Tube deformation | Replace tube and fitting |

| Gradual tightening over months | Dust or oil ingress | Replace fitting, improve filtration |

| Leakage after tube reinsertion | Tube hardening | Cut tube or replace |

Maintenance data from industrial automation plants shows higher leak rates after repeated tube reuse.

Choosing higher-quality Pneumatic fittings with consistent claw hardness and stable sealing materials reduces long-term maintenance issues. In applications with vibration or frequent disassembly, scheduled replacement is more cost-effective than emergency repair.Customers often discover that replacing a worn one touch fitting resolves system issues without changing valves or actuators. Recognizing tightness as a warning sign—not a benefit—protects equipment, uptime, and customer trust.

(FK9026)

PP Polypropylene Tube for High-Temperature Hot Water Transfer Systems

PP Polypropylene Tube for High-Temperature Hot Water Transfer Systems

Pneumatic Push-in Fitting Issues: Why Some SMC One Touch Fittings Get Tighter with Use

Pneumatic Push-in Fitting Issues: Why Some SMC One Touch Fittings Get Tighter with Use

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

You May Interest In

May 07, 2025 Blog

Comprehensive Analysis of Pneumatic Push in Fittings

Apr 22, 2025 Blog

Solution for Nylon Tube

Apr 16, 2025 Blog

PVC Tubing vs. Polyurethane Tubing

Apr 10, 2025 Blog

What is the difference between pu and pvc

Feb 24, 2025 Blog

How to Identify Hydraulic Quick Couplers?

Jan 21, 2025 Blog

How to Measure Pipe Thread?

Jan 16, 2025 Blog

What Is Pipe thread?

Dec 04, 2024 Blog

Application Of Tube Fitting

Jun 26, 2023 Blog

What Is The Difference Between LLDPE And LDPE?

Jan 17, 2023 Blog

What Are The Classification Of Plastics?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap