Jan 27, 2026

For industrial and automation applications, PP Polypropylene Tube stands out for its ability to form reliable, homogenous joints through hot melt welding. Unlike push-fit or adhesive connections, which rely on mechanical compression or chemical bonding, hot melt welding fuses the tube material itself, producing a permanent, leak-free connection. This property is particularly valued in fixed piping systems where long-term reliability and minimal maintenance are critical.

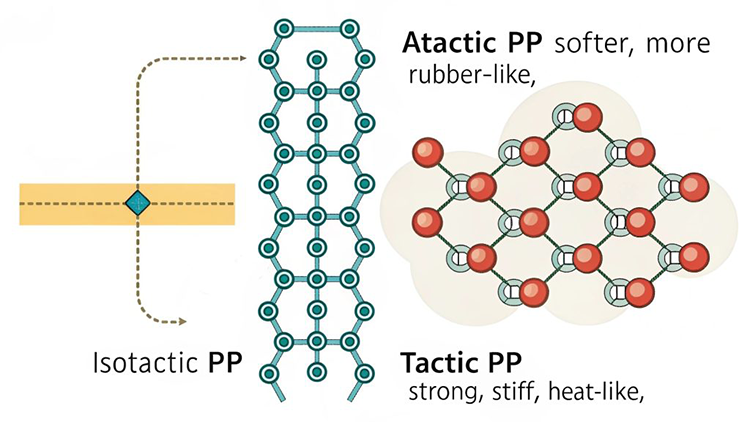

The key advantage of PP Polypropylene Hose lies in its thermoplastic nature. Polypropylene softens predictably under heat without degrading, allowing two tube sections to fuse completely. This homogenous fusion ensures uniform wall thickness and consistent internal flow characteristics, unlike glued or clamped connections where interface irregularities may form over time.

PP’s thermal stability also minimizes the risk of warping or deformation, a common concern when welding other polymers such as PVC.

Engineers often evaluate several connection methods for assembly efficiency and reliability:

| Connection Method | Reliability | Maintenance | Pressure Resistance | Typical Use |

|---|---|---|---|---|

| Hot Melt Welding | High | Minimal | High | Fixed piping, chemical transfer |

| Push-Fit Fittings | Medium | Periodic check | Moderate | Modular assemblies, easy disconnection |

| Adhesive Bonding | Low–Medium | Difficult to inspect | Moderate | Short-term, non-critical lines |

Data derived from industrial fluid handling standards.

As the table illustrates, hot melt welding provides superior long-term integrity, especially under thermal cycling or continuous flow conditions.

In industrial plants or chemical dosing systems, PP Polypropylene Tube welded connections maintain performance over years. The absence of intermediate materials (adhesives or mechanical clamps) reduces potential leak paths. This is why OEMs and plant engineers favor PP tubing for permanent installations, particularly when downtime must be minimized and maintenance schedules are strict.

When designing fixed piping systems:

1.Ensure tube ends are clean and cut squarely before welding.

2.Match welding temperature to tube diameter and wall thickness for uniform fusion.

3.Avoid mechanical stress on newly welded joints until fully cooled.

PP Polypropylene Tube paired with proper welding techniques achieves consistent, homogenous connections that outperform alternative joining methods in longevity and chemical resistance.

While hot melt welding is excellent for permanent, fixed systems, PP Polypropylene Hose may not be ideal in applications requiring frequent disconnection or dynamic flexing. Push-fit or quick-connect fittings remain practical in modular or mobile setups, but they cannot match the structural integrity and leak-free assurance of welded PP tubing.

By understanding the material’s unique properties and selecting the appropriate joining method, engineers and distributors can ensure reliable, maintenance-free operation in chemical, laboratory, or automation piping systems.

(FK9026)

Why Throttle Valves Cause Creeping at Low Speeds in Pneumatic Systems

Why Throttle Valves Cause Creeping at Low Speeds in Pneumatic Systems

Why PP Polypropylene Tube is Ideal for Hot Melt Welding in Fixed Piping Systems

Why PP Polypropylene Tube is Ideal for Hot Melt Welding in Fixed Piping Systems

PP Polypropylene Tube for High-Temperature Hot Water Transfer Systems

PP Polypropylene Tube for High-Temperature Hot Water Transfer Systems

Pneumatic Push-in Fitting Issues: Why Some SMC One Touch Fittings Get Tighter with Use

Pneumatic Push-in Fitting Issues: Why Some SMC One Touch Fittings Get Tighter with Use

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

You May Interest In

Jan 19, 2026 Blog

Signs It’s Time to Replace Your Pneumatic Nylon Tube

Jan 12, 2026 Blog

Air Brake Tube for Heavy-Duty Truck Braking Systems

Jan 09, 2026 Blog

How EPU Tubing Improves Abrasion ResistanceLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap