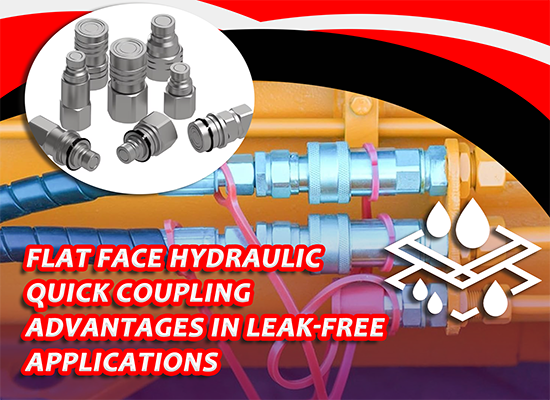

Air entering a hydraulic circuit often begins at the connection point of a Hydraulic Quick Coupling. Two couplers with the same size and pressure rating can behave very differently during connection and disconnection. The internal valve layout of a hydraulic quick connect coupler determines how much air is trapped and pushed into the system, and this directly affects stability, noise, and component life.

How air gets into a hydraulic line

When a Hydraulic Quick Connect is joined, a small cavity exists between the two valve faces. If this space is large or poorly sealed, the trapped air is forced into the oil flow at the next start. Frequent use of quick release couplings hydraulic on maintenance tools or test benches makes this effect even more obvious. The problem is not only visible bubbles; microscopic air reduces lubrication and creates compressibility inside the circuit.

Harm caused by air inclusion

Even a small amount of air can lead to unstable actuator movement and temperature rise. Pumps may produce cavitation noise, proportional valves respond slower, and seals age faster. In precision equipment such as plastic molding machines, air inclusion changes the real pressure curve and influences product quality. Therefore the design of a Hydraulic Quick Coupler must consider how to minimize this hidden risk.

Influence of valve core structure

Different internal structures of a hydraulic quick connect coupler generate different volumes of trapped air.

1.Flat-face valves leave almost no dead space when connected.

2.Poppet valves create a noticeable chamber between two cones.

3.Ball-type designs may trap air around the seat area.

The position of the sealing line is equally important. If the seal closes before the valves fully meet, the remaining cavity becomes a pocket of air. Low air inclusion design moves the sealing point closer to the flow path and shortens this pocket.

Low air inclusion design concept

Modern Hydraulic Quick Coupling with low air inclusion adopts several ideas:

1.Minimized internal cavity by flat or flush valve faces.

2.Optimized opening sequence so oil fills the space before final sealing.

3.Precise machining tolerance to avoid micro gaps.

4.Special surface treatment that improves wetting of hydraulic oil.

These details are invisible from the outside but decide how clean the connection really is.

Typical comparison

| Structure | Trapped volume | Connection force | Typical field |

|---|---|---|---|

| Flat-face | Very low | Medium | test equipment |

| Poppet | Medium | Low | general machinery |

| Ball type | Higher | Low | simple tools |

Application-based selection

Choosing the right Hydraulic Quick Coupler depends on how sensitive the system is to air.

◆Servo or closed-loop systems require the lowest air inclusion.

◆Mobile equipment with large cylinders can tolerate medium levels.

◆Flushing lines focus more on flow than on air control.

For frequent maintenance connections, flat-face hydraulic quick connect coupler is usually the safest option, while traditional poppet types suit less critical circuits.

Practical tips for buyers

Before ordering quick release couplings hydraulic, ask a few practical questions:

◆Will the connection be made under residual pressure?

◆How often is the line opened each day?

◆Does the machine include proportional or servo valves?

◆Is oil cleanliness a strict requirement?

Clear answers help avoid choosing a low-cost model that later causes expensive troubleshooting. Our hydraulic quick coupling products include low air inclusion versions designed for precision systems.

Better connection, healthier system

Air problems in hydraulics often look mysterious, yet the root is frequently the connector. A carefully designed Hydraulic Quick Coupling can keep the oil column continuous and protect pumps, valves, and seals for years. Understanding the relation between valve structure and air inclusion allows distributors to recommend more professional solutions and enables engineers to build quieter, more reliable machines.

(FK9026)