Jan 30, 2026

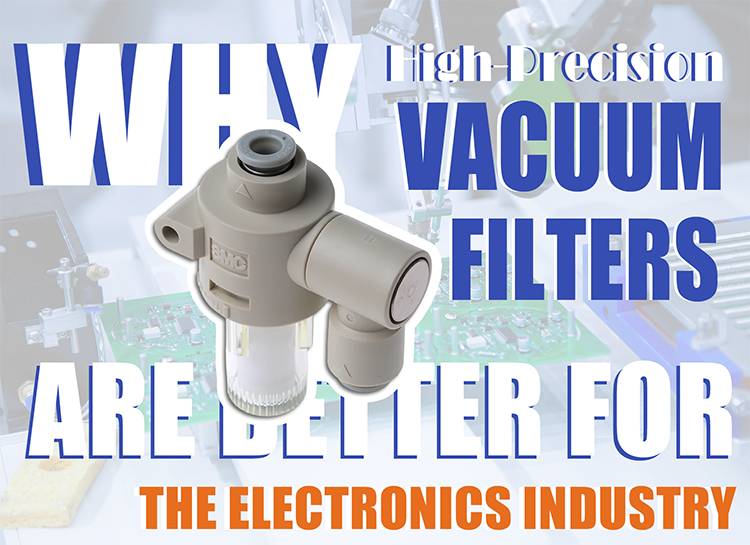

In electronics manufacturing, even microscopic contaminants can cause serious quality issues. A properly selected vacuum filter plays a critical role in protecting vacuum systems used for component handling, inspection, and assembly. In high-cleanliness environments, filtration is not just a supporting function—it directly affects yield, equipment stability, and long-term maintenance costs.

During electronic component transfer, dust smaller than 10 microns can enter the vacuum line through suction cups or open ports. Once inside, these particles can affect airflow stability and sealing performance. Using a high-precision SMC vacuum filter helps capture fine contaminants before they reach sensitive downstream components, ensuring consistent vacuum pressure during pick-and-place operations.

A venturi vacuum generator relies on clean compressed air to maintain stable vacuum output. Contaminants entering the system may lead to nozzle blockage or pressure loss. Installing a high-efficiency vacuum filter upstream significantly reduces internal wear and prevents unexpected downtime. In electronics lines operating continuously, this protection is essential for maintaining production rhythm.

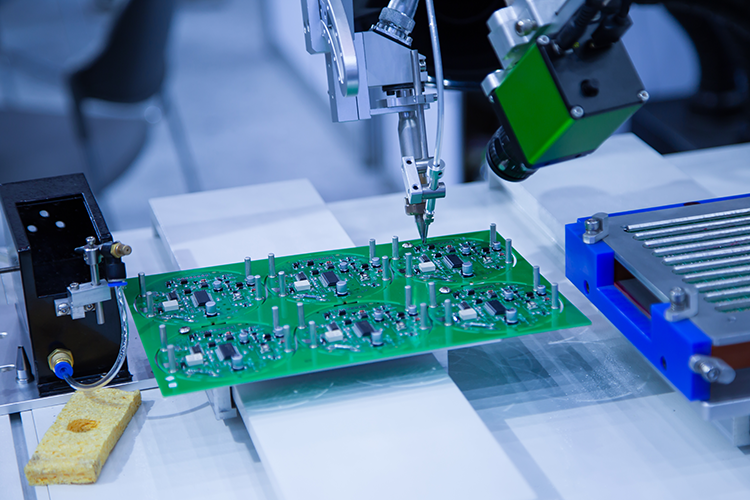

Compared with general industrial automation, electronics production environments demand stricter contamination control. Fine solder dust, plastic debris, and packaging residues are common. A high-precision pneumatic vacuum generator combined with appropriate filtration minimizes these risks and ensures smooth, repeatable operation even in compact assembly equipment.

Vacuum filters are commonly applied in semiconductor packaging, PCB assembly, and small component sorting. Their compact design allows easy integration close to the suction point, reducing particle travel distance. When paired with an vacuum generator, the system delivers fast response and stable holding force, which is critical for fragile electronic parts.

| Filtration Level | Particle Size Captured | Suitable Application |

|---|---|---|

| Standard Filter | ≥20 μm | General automation |

| Medium Precision | ≥10 μm | Light electronics handling |

| High Precision Vacuum Filter | ≤5 μm | Semiconductor & PCB processes |

Higher filtration accuracy improves cleanliness but may introduce slight pressure loss. Selecting the correct balance is a key consideration during system design.

When choosing a vacuum generator for electronics applications, engineers should consider filtration accuracy, airflow capacity, and maintenance accessibility. Modular SMC vacuum generator systems allow filters to be replaced quickly without disassembling the entire vacuum circuit, reducing maintenance time and minimizing production interruption.

By integrating high-precision vacuum filters with reliable vacuum generation components, electronics manufacturers can achieve cleaner handling processes, improved equipment protection, and more predictable system performance.

(FK9026)

Hydraulic Quick Coupling Why Some Quick Connects Allow More Air Inclusion

Hydraulic Quick Coupling Why Some Quick Connects Allow More Air Inclusion

How to Choose the Right Hydraulic Quick Coupler: Types, Features, and Applications

How to Choose the Right Hydraulic Quick Coupler: Types, Features, and Applications

Why High-Precision Vacuum Filters Are Better for the Electronics Industry

Why High-Precision Vacuum Filters Are Better for the Electronics Industry

Brass compression fittings: Reliable Solutions for Secure Connections

Brass compression fittings: Reliable Solutions for Secure Connections

Stainless Steel Push to Connect Fittings for Drinking Water Systems

Stainless Steel Push to Connect Fittings for Drinking Water Systems

You May Interest In

Jan 21, 2025 Blog

How to Measure Pipe Thread?

Dec 12, 2024 Customer Case

Multi-Row Pu Hose Customization

Sep 10, 2023 Blog

How To Differentiate And Select Teflon Pipe?

Sep 07, 2025 Blog

Rubber hose vs. PVC tubing How to choose?

Aug 13, 2025 Blog

The Benefits and Uses of Ethylene Vinyl Acetate

Dec 10, 2025 Blog

How to Choose and Use Rapid Pneumatic FittingsLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap