Feb 02, 2026

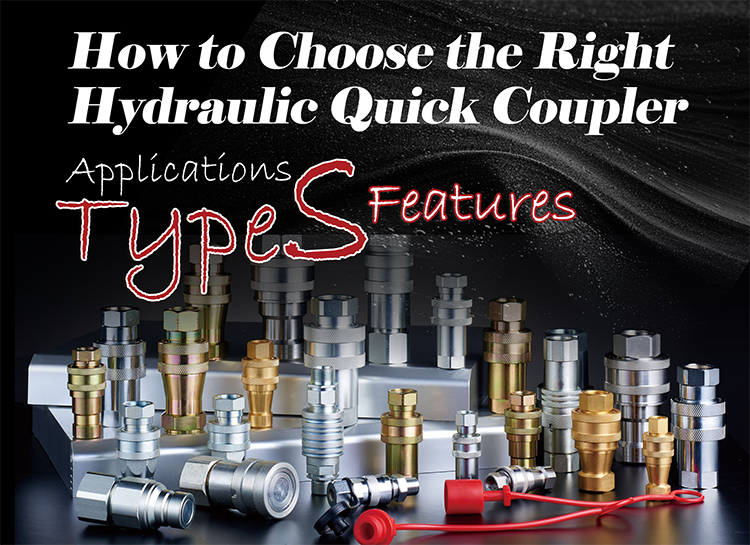

Hydraulic Quick Coupling components are the connection points that determine whether a hydraulic system remains safe, clean, and efficient. A correctly chosen hydraulic quick connect coupler reduces leakage, shortens maintenance time, and protects pumps and valves. For distributors, engineers, and purchasing managers, understanding the logic behind selection is more valuable than simply matching thread size.

A hydraulic fitting is the mechanical interface that links hoses, pipes, and equipment ports to create a sealed fluid path. Modern Quick Connect products allow fast disconnection without major oil loss, which is essential for mobile machinery and industrial lines. Beyond connection, the fitting must withstand vibration, pressure pulses, temperature change, and chemical exposure. The quality of a Hydraulic Quick Coupler therefore directly influences system reliability and operating cost.

Hydraulic fittings can be permanent crimped types or reusable screw-on types. Permanent solutions connect quickly with crimping machines and provide high and consistent reliability. Reusable fittings were popular in the past, but today they are less common because installation takes longer and the sealing result depends heavily on operator skill.

Correct port matching is the foundation of safety. There are many standards such as BSP, NPT, JIC, and metric. Choosing a hydraulic quick connect coupler with the wrong port leads to micro leakage or thread damage even if the size looks similar. Identifying the exact standard before ordering saves costly field modifications.

Different designs rely on O-rings, metal-to-metal cones, or angle seating to create a seal. The working pressure, temperature, and fluid type decide which method is appropriate. For high vibration equipment, elastic sealing usually performs better than rigid taper threads.

Although the market offers hundreds of models, three structures appear most frequently in quick release couplings hydraulic.

1.ISO hydraulic couplings –ISO hydraulic couplings are designed in accordance with international standards and can be used for quick connections as well as high-pressure threaded connections.

2.O-ring fittings – A rubber O-ring is placed around the male component to ensure sealing when connected with the female part. This design provides stable sealing under dynamic load and is easy to service.

3.Tapered thread fittings – The male part has external threads and the female part internal threads. Tightening them together forms a seal. They are simple and widely used but more sensitive to over-tightening.

4.Mating angle fittings – The seal is created by the angle of the internal cone surfaces. These fittings tolerate high pressure and are common in heavy industrial equipment.

| Type | Vibration resistance | Ease of assembly | Typical use |

|---|---|---|---|

| O-ring | Excellent | Easy | mobile hydraulics |

| Taper thread | Medium | Simple | general machinery |

| Mating angle | Very good | Moderate | high pressure units |

Modern fittings are designed with additional functions to suit different machines.

◆Flexible joints allow limited movement without damage, useful on articulated equipment.

◆Expansion joints compensate for heavy load, impact, or high temperature.

◆Rotary joints permit continuous rotation of hoses.

◆Pressure connect fittings enable connection under residual pressure, a practical option for field maintenance.

Understanding these features helps choose a Hydraulic Quick Coupling that matches the real working behavior rather than only the catalog picture.

When selecting a hydraulic quick connect coupler, start from the application scenario:

◆Identify pressure range and possible pressure peaks.

◆Confirm fluid type and temperature.

◆Check space for installation and required connection frequency.

◆Decide whether fast maintenance or absolute cleanliness is the priority.

This logic is more reliable than picking the cheapest item.

Choosing hydraulic fittings is not a single technical decision but a balance between safety, maintenance efficiency, and budget. A well-selected Hydraulic Quick Coupler reduces downtime and protects the whole system for years. Distributors can use these principles to explain differences to customers, and engineers can translate machine requirements into concrete specifications.

(FK9026)

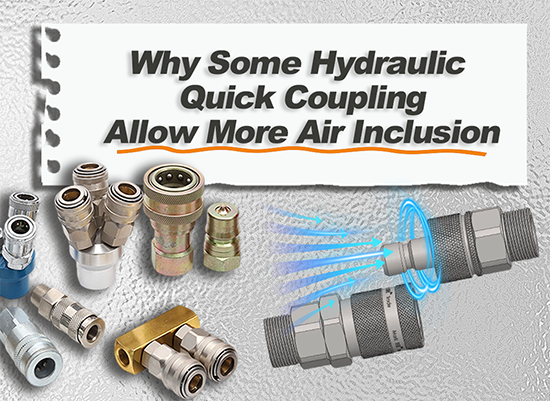

Why Some Hydraulic Quick Coupling Allow More Air Inclusion

Why Some Hydraulic Quick Coupling Allow More Air Inclusion

How to Choose the Right Hydraulic Quick Coupler: Types, Features, and Applications

How to Choose the Right Hydraulic Quick Coupler: Types, Features, and Applications

Why High-Precision Vacuum Filters Are Better for the Electronics Industry

Why High-Precision Vacuum Filters Are Better for the Electronics Industry

Brass compression fittings: Reliable Solutions for Secure Connections

Brass compression fittings: Reliable Solutions for Secure Connections

Stainless Steel Push to Connect Fittings for Drinking Water Systems

Stainless Steel Push to Connect Fittings for Drinking Water Systems

You May Interest In

May 07, 2025 Blog

Comprehensive Analysis of Pneumatic Push in Fittings

Apr 22, 2025 Blog

Solution for Nylon Tube

Apr 16, 2025 Blog

PVC Tubing vs. Polyurethane Tubing

Apr 10, 2025 Blog

What is the difference between pu and pvc

Feb 24, 2025 Blog

How to Identify Hydraulic Quick Couplers?

Jan 21, 2025 Blog

How to Measure Pipe Thread?

Jan 16, 2025 Blog

What Is Pipe thread?

Dec 04, 2024 Blog

Application Of Tube Fitting

Jun 26, 2023 Blog

What Is The Difference Between LLDPE And LDPE?

Jan 17, 2023 Blog

What Are The Classification Of Plastics?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap