Aug 13, 2025

You will find that industries such as photovoltaic encapsulation films, shoe midsoles, electronic protective pads, sports equipment, and medical device accessories are increasingly adopting EVA copolymer materials. This is due not only to EVA's excellent flexibility, weather resistance, and thermal stability, but also because its processing can be adjusted to meet application needs, achieving diverse properties ranging from high elasticity cushioning to high transparency. This article introduces its thermal properties and applications.

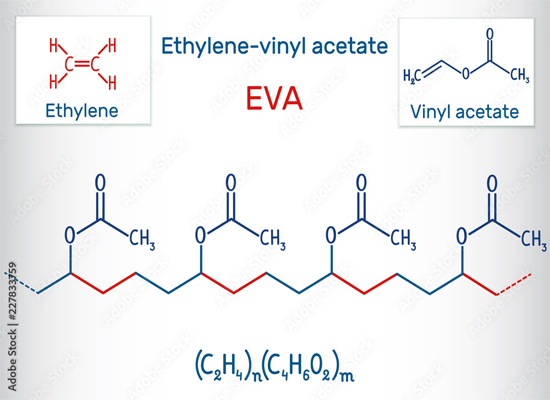

Ethylene vinyl acetate (EVA) is a thermoplastic copolymer made from ethylene and vinyl acetate. This material combines the rigidity of ethylene with the flexibility and adhesion of vinyl acetate. The properties of the copolymer vary depending on the ratio of ethylene to vinyl acetate; when ethylene content is higher than vinyl acetate, the material tends to be more rigid and wear-resistant.

EVA's main applications involve insulation and protection, owing to its excellent thermal properties, such as:

Thermoplasticity: EVA is a typical thermoplastic elastomer that softens when heated and hardens upon cooling. This feature is particularly useful in shoe midsoles and insoles for cushioning and durability.

Adjustable Low Melting Point: The low melting point of EVA can be tuned mainly by the vinyl acetate content; higher VA content results in a lower melting point, making the material softer, more transparent, and suitable for use at lower temperatures; lower VA content raises the melting point, resulting in harder materials with higher heat resistance. This allows flexibility in balancing softness and temperature resistance during processing.

Thermal Adhesion: EVA’s ability to melt and bond firmly to materials like fabrics, rubber, and metals after heating is closely related to its VA content, making it widely used in hot melt adhesives and film lamination.

Excellent Flexibility and Elasticity

The addition of vinyl acetate reduces molecular crystallinity and intermolecular forces, allowing polymer chains to slide and recover more easily.

Good Chemical Resistance and Weatherability

EVA has a stable structure with moderate crystallinity and tight molecular bonding. It is often combined with antioxidants and UV absorbers to enhance resistance to UV and aging.

Low-Density Lightweight Material

EVA foam has low density and weight, greatly improving its thermal insulation properties. EVA foam tubing, made from foamed EVA, has better insulation and elasticity compared to solid EVA tubing.

Good Transparency and Optical Properties

EVA can be made into transparent materials widely used in photovoltaic encapsulation films and packaging films.

Environmentally Friendly

Though EVA is not biodegradable, it is recyclable, especially in footwear and packaging industries. Some manufacturers are also developing biodegradable materials with similar performance.

Cost-Effective

Ethylene-based materials have relatively low prices and low processing costs, offering high cost performance.

Footwear Industry: Used in shoe soles and cushioning pads requiring elasticity and wear resistance.

Packaging Industry: EVA foam materials serve as lightweight thermal insulation films and composite films.

Construction and Automotive: EVA foam materials are used for insulation, shock absorption, and cushioning.

Photovoltaic Industry: EVA polymers'stable structure and good weather resistance make them ideal as protective layers.

Adhesive Industry: EVA's ability to harden after melting is applied in bonding and connecting fractured parts in electronics.

Thermal properties of Ethylene Vinyl Acetate include thermoplasticity (softening when heated and hardening on cooling with repeatable melting), adjustable low melting point for flexible processing, foaming with thermal insulation properties, and strong heat adhesion allowing firm bonding with various surfaces.

Due to material differences, EVA foam tubing is usually soft and elastic, while solid EVA tubing is more rigid but still somewhat elastic. Both EVA foam tubes and PE foam tubes have excellent softness and resilience, but EVA foam tubes offer higher strength and durability, whereas PE foam tubes are more economical.

If you want more information about EVA material or eva copolymer,contact us directly or you browse our website:www.fokcaflow.com

EVA materials feature flexibility, lightweight, excellent weather resistance, and strong thermoplasticity.

Widely used in footwear, packaging, sports, automotive, medical industries, and also as materials for EVA tubes and foam tubing.

Yes, EVA is non-toxic, recyclable, and environmentally friendly.

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

May 07, 2025 Blog

Comprehensive Analysis of Pneumatic Push in Fittings

Apr 22, 2025 Blog

Solution for Nylon Tube

Apr 16, 2025 Blog

PVC Tubing vs. Polyurethane Tubing

Apr 10, 2025 Blog

What is the difference between pu and pvc

Feb 24, 2025 Blog

How to Identify Hydraulic Quick Couplers?

Jan 21, 2025 Blog

How to Measure Pipe Thread?

Jan 16, 2025 Blog

What Is Pipe thread?

Dec 04, 2024 Blog

Application Of Tube Fitting

Jun 26, 2023 Blog

What Is The Difference Between LLDPE And LDPE?

Jan 17, 2023 Blog

What Are The Classification Of Plastics?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap