Jan 28, 2026

Proper sealing is essential in pneumatic systems to prevent leaks and maintain efficiency. For distributors, engineers, and procurement managers, knowing which fittings require PTFE tape—commonly called thread seal tape or Teflon tape—is critical. While many fittings achieve tight connections through mechanical deformation, some threaded connections still need additional sealing to ensure reliability.

PTFE thread seal tape is a versatile sealing material widely used in daily plumbing applications, including faucets, pipes, and shower systems. In pneumatic systems, its purpose is to fill minor gaps in threaded connections and enhance sealing integrity. However, not all pneumatic fittings require PTFE tape, as some rely on other sealing methods.

Certain pneumatic fittings, such as push-to-connect fittings and compression fittings, seal through mechanical deformation. In a push-to-connect fitting, the internal O-ring and ferrule compress the tubing upon insertion, while compression fittings rely on metal sleeve deformation.

Adding PTFE tape in these cases is unnecessary and can even hinder proper fitting performance.

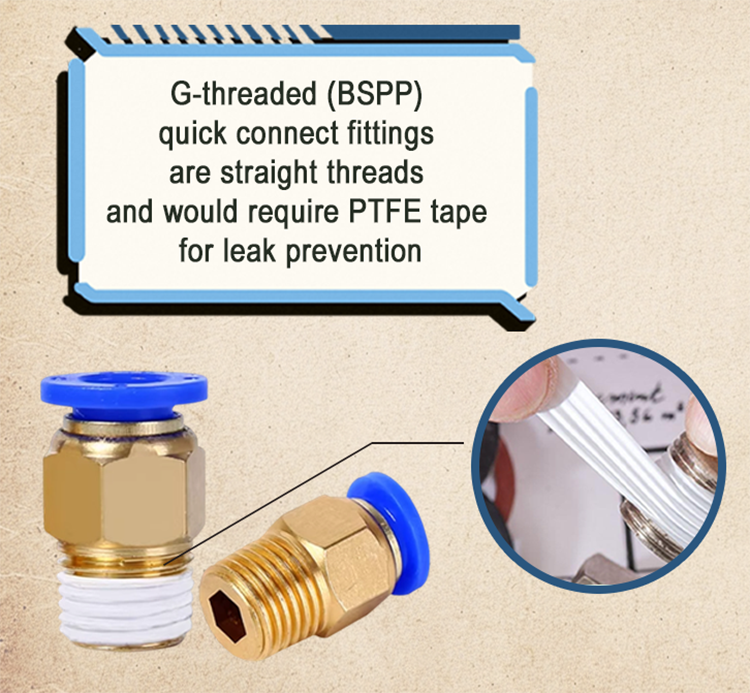

In theory, G-threaded (BSPP) quick connect fittings are straight threads and would require PTFE tape for leak prevention. Conversely, tapered threads like BSPT and NPT are designed to be self-sealing. In practice, the opposite often occurs:

| Thread Type | Sealing Mechanism | PTFE Tape Needed? |

|---|---|---|

| G-thread (BSPP) | Straight thread + sealing washer or O-ring | No, typically not needed |

| BSPT / NPT | Tapered thread | Yes, recommended due to machining tolerances |

Table illustrates practical sealing guidance for pneumatic quick coupling connections.

Because of machining tolerances and thread interference, PTFE tape strengthens the seal on BSPT and NPT fittings, while G-threaded fittings are usually paired with a sealing ring, eliminating the need for tape.

When installing pneumatic quick connect fittings or quick connect hose fittings, the correct approach is:

1.Check the thread type: Identify whether the fitting is straight (BSPP/G) or tapered (BSPT/NPT).

2.Use PTFE tape selectively: Only apply on tapered threads where leakage is possible.

3.Avoid overuse: Excess tape on self-sealing or O-ring fittings can prevent proper engagement.

This ensures optimal sealing performance without unnecessary material use or installation complications.

Proper use of PTFE tape in pneumatic systems:

◆Reduces air leaks and maintenance costs

◆Ensures consistent system performance

◆Simplifies installation by preventing repeated tightening or rework

Distributors and end users can rely on FOKCA Automation’s range of push-to-connect fittings, pneumatic quick couplings, and quick connect hose fittings, which are engineered for reliable sealing and compatibility with standard thread types.

Correctly understanding which fittings require PTFE tape helps engineers and procurement teams prevent leaks, improve efficiency, and maintain long-term reliability in industrial pneumatic systems.

(FK9026)

Pneumatic Push In Fittings: When to Use PTFE Thread Seal Tape

Pneumatic Push In Fittings: When to Use PTFE Thread Seal Tape

Why is PA11 considered more environmentally friendly and sustainable

Why is PA11 considered more environmentally friendly and sustainable

Why Throttle Valves Cause Creeping at Low Speeds in Pneumatic Systems

Why Throttle Valves Cause Creeping at Low Speeds in Pneumatic Systems

Why PP Polypropylene Tube is Ideal for Hot Melt Welding in Fixed Piping Systems

Why PP Polypropylene Tube is Ideal for Hot Melt Welding in Fixed Piping Systems

PP Polypropylene Tube for High-Temperature Hot Water Transfer Systems

PP Polypropylene Tube for High-Temperature Hot Water Transfer Systems

You May Interest In

Dec 15, 2024 Customer Case

Metallic tube Customization

Apr 17, 2023 Blog

What Are The Differences In Nylon

May 21, 2025 Blog

The Difference Between Flexible and Rigid PVC Pipe

May 14, 2025 Blog

What is Rubber Hose?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap