Jan 16, 2026

In compressed air systems, pneumatic silencers are often treated as small, low-cost accessories. In reality, they play a critical role in noise reduction, exhaust flow control, and protection of downstream components.

When a silencer becomes clogged with oil mist, dust, or carbon residue, a common question arises on the shop floor: can it be cleaned and reused, or should it be replaced entirely?

The answer depends largely on material, structure, operating environment, and cost considerations.

A pneumatic exhaust silencer works by diffusing high-speed exhaust air through porous media or internal chambers. During operation, especially in oil-lubricated compressed air systems, exhaust air often carries oil mist, fine particles, moisture, and degradation byproducts.

Over time, these contaminants accumulate inside the silencer, leading to:

1.Increased exhaust back pressure

2.Reduced noise reduction effectiveness

3.Slower actuator response

4.Potential pressure buildup affecting valves or cylinders

In air compressor systems or high-duty pneumatic equipment, this buildup is not an exception—it is expected.

Yes, many pneumatic silencers can be cleaned and reused, but not all of them are worth cleaning.

From an engineering and economic perspective, the decision depends on:

◆Silencer body material

◆Internal structure

◆Exposure to oil, chemicals, or moisture

◆Replacement cost versus labor cost

Understanding these factors helps engineers and buyers make rational maintenance decisions rather than relying on habit.

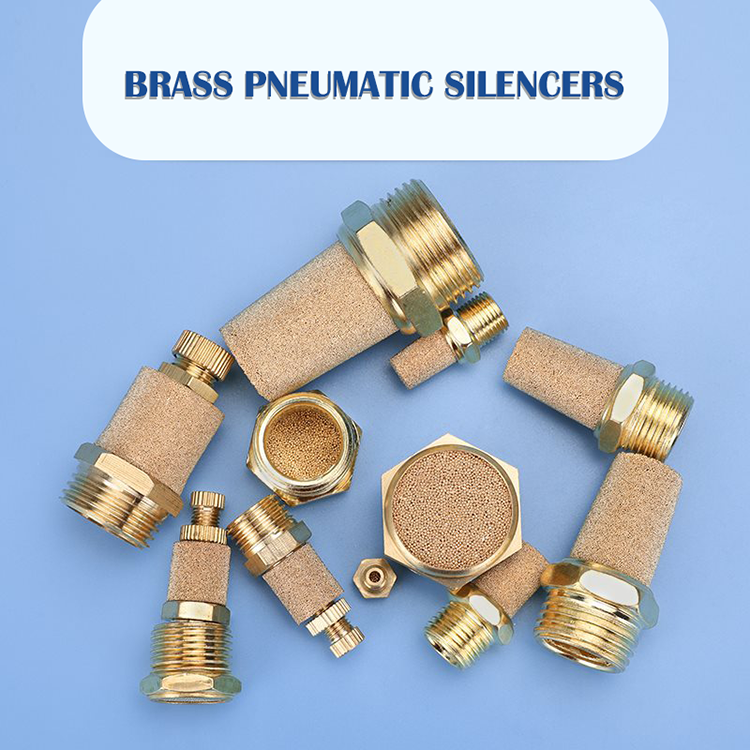

Brass pneumatic silencers and stainless steel pneumatic silencers are generally well suited for cleaning and reuse.

These metal silencers are commonly used in:

◆Industrial automation lines

◆CNC machinery

◆Air compressor exhaust systems

◆Continuous-duty pneumatic circuits

Metal-bodied pneumatic exhaust mufflers offer several advantages:

◆High corrosion resistance, especially stainless steel

◆Strong resistance to solvents and detergents

◆Structural integrity after repeated cleaning

◆Stable threaded connections even after disassembly

Oil residue, carbon buildup, or dust can usually be removed using:

◆Industrial degreasers

◆Alcohol-based solvents

◆Ultrasonic cleaning (for stainless steel)

◆Compressed air flushing after cleaning

Once cleaned and dried, the silencer can often return to near-original performance.

Plastic pneumatic silencers are widely used due to their low cost and lightweight design. They are common in:

◆Compact machinery

◆Cost-sensitive OEM equipment

◆Light-duty pneumatic systems

From a technical standpoint, plastic silencers can be cleaned, but the results are mixed.

Plastic materials have:

1.Lower solvent resistance

2.Higher risk of deformation

3.Porous structures that trap oil residue

4.Reduced mechanical strength after repeated exposure

After cleaning, a plastic pneumatic silence component may:

◆Lose noise reduction efficiency

◆Crack during reinstallation

◆Show reduced airflow consistency

For this reason, many engineers treat plastic silencers as semi-consumable components.

From a purchasing and maintenance perspective, the key question is not whether a silencer can be cleaned, but whether it should be.

| Silencer Type | Material | Cleanability | Reuse Value | Typical Decision |

|---|---|---|---|---|

| Pneumatic exhaust silencer | Brass | Excellent | High | Clean and reuse |

| Pneumatic exhaust muffler | Stainless steel | Excellent | Very high | Clean and reuse |

| Pneumatic silencer | Plastic | Moderate | Low | Replace |

| Air compressor exhaust silencer | Metal | Excellent | High | Clean and reuse |

For higher-priced metal silencers, cleaning significantly extends service life and reduces downtime.

For low-cost plastic silencers, replacement often provides better cost-performance once labor and reliability are considered.

Ignoring a clogged pneumatic exhaust muffler does more than increase noise.

Common system-level effects include:

1.Slower cylinder return speed

2.Increased exhaust pressure

3.Higher energy consumption

4.Valve malfunction due to pressure imbalance

In air compressor exhaust applications, clogged silencers can also cause localized heat buildup, accelerating material aging in nearby components.

Routine inspection and timely cleaning or replacement help maintain system efficiency and predictable performance.

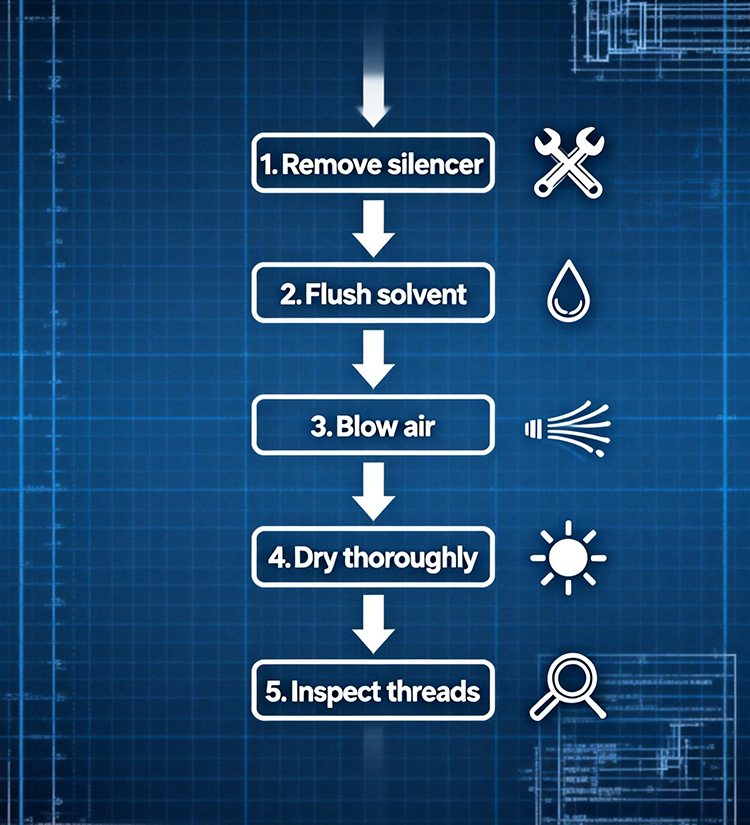

For brass and stainless steel pneumatic silencers, the following approach is commonly used in industrial maintenance:

1.Remove the silencer from the exhaust port

2.Flush with suitable industrial solvent

3.Use compressed air to blow out loosened contaminants

4.Dry thoroughly before reinstallation

5.Inspect threads and sealing surfaces

Aggressive mechanical cleaning is usually unnecessary and may damage internal diffusion structures.

Cleaning and reusing pneumatic silencers is not only possible—it is often the preferred maintenance approach for metal silencers.

For plastic silencers, replacement is frequently the more economical and reliable choice.

Understanding this distinction helps engineers, buyers, and maintenance teams make data-driven decisions, rather than treating all silencers as disposable parts.

(FK9026)

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

PUAS Polyurethane Tubing: Flexible, Durable, and Anti-Static Solution for Industrial Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Which Pneumatic Fittings Perform Best in High-Vibration Applications

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Pneumatic Tubing Should Not Be Bent Immediately After an SMC One Touch Fitting

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Aluminum Foil Is Added to PUFR Flame-Resistant Hose and How It Improves Fire Performance

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

Why Nylon Hose Leaks: The Real Causes Behind Air Loss at Fittings

You May Interest In

May 07, 2025 Blog

Comprehensive Analysis of Pneumatic Push in Fittings

Apr 22, 2025 Blog

Solution for Nylon Tube

Apr 16, 2025 Blog

PVC Tubing vs. Polyurethane Tubing

Apr 10, 2025 Blog

What is the difference between pu and pvc

Feb 24, 2025 Blog

How to Identify Hydraulic Quick Couplers?

Jan 21, 2025 Blog

How to Measure Pipe Thread?

Jan 16, 2025 Blog

What Is Pipe thread?

Dec 04, 2024 Blog

Application Of Tube Fitting

Jun 26, 2023 Blog

What Is The Difference Between LLDPE And LDPE?

Jan 17, 2023 Blog

What Are The Classification Of Plastics?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap