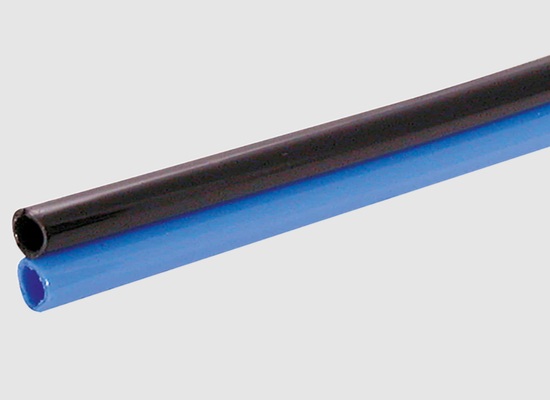

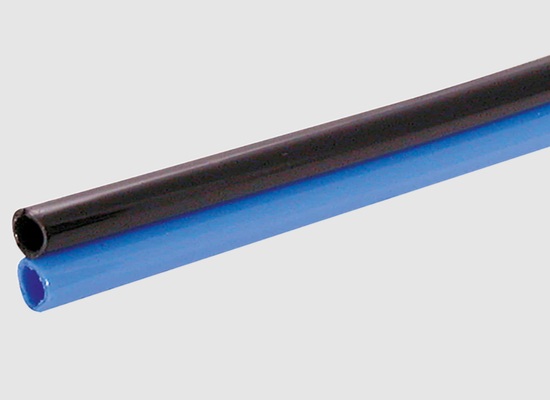

Black polyurethane tubing is widely chosen for pneumatic, hydraulic, and fluid-transfer systems because of its unique blend of flexibility, abrasion resistance, and compatibility with oils and fuels. The black formulation adds UV protection, reduces light penetration, and keeps lines looking clean even in demanding environments. Understanding its design, performance features, and common applications helps engineers, buyers, and maintenance teams select tubing that meets both technical requirements and long-term reliability goals.

What Is Polyurethane Tubing and Why Choose Black PU?

Polyurethane tubing is a flexible, durable hose made from thermoplastic polyurethane (TPU), a material valued for its high abrasion resistance, elasticity, and resistance to oils, fuels, and many chemicals. It is commonly used in pneumatic systems, fluid transfer, and automotive or industrial applications where both flexibility and strength are required.

Black polyurethane tubing offers the same core properties but with added benefits: the black pigmentation provides better protection against UV light, reduces light transmission through the walls of the tube, and helps conceal dirt or discoloration in demanding environments. These features make black PU tubing a preferred choice for outdoor, high-wear, or visually exposed installations where long service life and consistent performance are important.

Features and Specifications of Black Polyurethane Pipe

1. Flexible yet Strong Construction

Black polyurethane pipe is made from thermoplastic polyurethane, giving it high tensile strength and excellent flexibility even in tight routing spaces. This makes it ideal for pneumatic, hydraulic, and general fluid transfer applications where bending without kinking is required.

2. Wide Range of Standard Sizes

It is manufactured in multiple inner and outer diameters to match common systems, such as 1/4-inch (often referred to as polyurethane tubing 14) and 3/8-inch (polyurethane air hose 38). These standardized sizes allow easy integration with fittings and PU tube connectors in industrial or automotive setups.

3. UV and Light Protection

The black pigmentation provides greater UV resistance than clear or colored versions. This helps slow down material degradation and prevents algae growth inside the tube by reducing light penetration, making it more suitable for outdoor and exposed installations.

4. Fuel and Chemical Resistance

Polyurethane tubing is naturally resistant to many oils, fuels, and chemicals. Black polyurethane pipe performs well for gasoline and other hydrocarbon-based fluids, offering an advantage over some softer plastics that may swell or crack. However, users should always confirm compatibility with their specific fluid before use.

5. Drinking Water and Safety Considerations

Some grades of polyurethane tubing are manufactured with food- or water-contact approvals, making them safe for certain drinking water or beverage systems. For critical applications, buyers should check the product’s certification (FDA, NSF, etc.) to ensure compliance with local regulations before using it in potable water systems.

What Is Polyurethane Tubing Used For?

Pneumatic Systems: Its flexibility and pressure resistance make polyurethane tubing a standard choice for air lines in automation, robotics, and other pneumatic equipment.

Fuel and Oil Transfer: Because it resists many hydrocarbons, polyurethane tubing is often used for gasoline, diesel, and lubricating oil lines in small engines, vehicles, and machinery.

Water and Beverage Delivery: Certain food-grade versions are used to convey water or beverages in vending machines, coffee makers, or low-pressure water systems, provided they meet the relevant safety certifications.

Automotive and Industrial Maintenance: It serves as a durable hose for fluid transfer, vacuum lines, and protective covers in cars, trucks, and heavy equipment.

Laboratory and Chemical Handling: Polyurethane tubing’s chemical resistance and clarity (in non-black versions) make it suitable for moving or sampling many non-corrosive liquids in labs and pilot plants.

Protective or Insulating Sleeves: In addition to carrying fluids, polyurethane tubing is also used as a sleeve to protect wires, cables, or fragile components from abrasion and impact in demanding environments.

Comparing Materials: Polyurethane vs Other Tubing Options

Polyurethane vs. Nylon Tubing

Polyurethane tubing is softer and more flexible than nylon, which makes it easier to route through tight spaces or around moving parts without kinking. Nylon tubing, by contrast, is stiffer and holds its shape better, which can be an advantage in long, straight runs where minimal flex is desired. In terms of chemical resistance, nylon generally withstands a wider range of solvents and higher pressures than standard polyurethane, making it a better choice for aggressive chemicals or high-pressure systems.

However, polyurethane performs well with oils, fuels, and many common industrial fluids while offering superior impact and abrasion resistance. For temperature range, nylon can typically handle higher continuous service temperatures, while polyurethane remains flexible in lower temperatures and is less prone to cracking in cold environments.

Black Polyurethane Pipe vs. Black Poly Tubing

Black polyurethane pipe combines flexibility with good fuel and oil resistance, making it suitable for pneumatic air lines, gasoline transfer, and applications where abrasion resistance is important. Black poly tubing (often referring to high-density polyethylene or HDPE “black poly” rolls) is stiffer, typically used for underground or above-ground water distribution, irrigation, and low-pressure fluid transfer.

In other words, black polyurethane pipe is generally the better fit for air systems, fuel lines, and dynamic installations, while black poly tubing excels in long-term, mostly static water applications such as irrigation or main water feeds.

Specialized Use Cases of Black Polyurethane Tubing

Outdoor and UV-Exposed Installations: Unlike clear or colored polyurethane tubing, black polyurethane tubing has added pigmentation that improves UV resistance and blocks light transmission, making it more suitable for outdoor air lines, irrigation controls, or exposed pneumatic systems.

Fuel and Hydrocarbon Transfer: Black polyurethane tubing is often chosen over standard versions for gasoline, diesel, and oil transfer lines because its darker formulation offers slightly better fuel compatibility and hides staining from hydrocarbons.

Concealed or Aesthetic Installations: In environments where appearance matters—such as visible pneumatic lines in machinery, equipment racks, or display systems—the black color masks dirt and discoloration better than clear tubing, giving a cleaner look and reducing maintenance visibility.

Where to Source Black Polyurethane Tube?

Local Hardware and Industrial Supply Stores

Many local hardware shops, pneumatic distributors, and industrial supply houses stock common sizes of black polyurethane tubing. These outlets are convenient for small or urgent orders because you can see the product in person, check markings, and ensure the size matches your fittings. Big-box stores and regional distributors may also carry rolls of black poly pipe for water systems alongside polyurethane air hoses.

Online Suppliers Fokcaflow.com

Fokcaflow.com is the official site of Fokca, a manufacturer with over 15 years of experience producing flexible hoses, including black polyurethane tubing. The company operates more than 30 production lines under strict 6S management and advanced testing to meet ISO9001, TS16949, CE, FDA, and ROHS standards. It offers a full range of PU, nylon, PE, PVC, and specialty hoses in standard sizes (such as 1/4-inch and 3/8-inch) as well as custom OEM options. With a global customer base in over 36 countries, Fokcaflow.com provides direct factory pricing, consistent quality, and technical support, making it a reliable online source for black polyurethane tubing.