Introduction

With the continuous advancement of material science and manufacturing technology, plastic tubing is playing an increasingly important role in both modern industrial and civil applications. Whether in building water supply and drainage systems, pneumatic transmission lines, or in fields such as medical devices, automotive systems, cable sheathing, and agricultural irrigation, plastic tubing has been widely adopted due to its lightweight nature, corrosion resistance, and excellent flexibility—gradually replacing traditional metal pipes and certain types of thermosetting plastic pipes.

Among them, thermoplastic plastic tubing stands out for its excellent processability, chemical stability, lower production cost, and ease of recycling. Compared to thermosetting plastic pipes, it offers better plasticity and can be reshaped through repeated heating. In contrast to metal tubing, thermoplastics are lighter, more corrosion-resistant, and easier to install.

Thermoplastic tubing has thus become an indispensable core material in modern fluid transport systems and structural pipeline design.

What is thermoplastic tubing

Definition and basic principles

Thermoplastic pipes are tubular products made from polymer materials with thermoplastic characteristics, such as PP and PE, processed through extrusion, injection molding, and other processes. When heated to a certain temperature, this type of plastic will soften or melt, and can be processed to form other shapes of pipelines; After cooling, it returns to a solid structure. This reversible physical change gives thermoplastic pipes good processability and repeatable forming characteristics. It can greatly save costs.

Common thermoplastic material pipes

In the actual production of thermoplastic pipes, common thermoplastic pipes include:

Polyurethane: Thermoplastic polyurethane offers excellent flexibility and wear resistance, making it suitable for pneumatic and hydraulic piping.

Nylon: A thermoplastic engineering plastic with excellent hardness, rigidity, and impact resistance. It is used in pneumatic and industrial wear-resistant pipes.

Polyolefin: A thermoplastic that is lightweight and chemically stable, making it suitable for drainage pipes and chemical fluid transportation.

Fluororesin:A thermoplastic resin with strong chemical stability, a wide temperature range, and a smooth, non-sticky surface. It is used in pipelines with highly corrosive media.

Polyvinyl chloride:A thermoplastic with low cost and high acid, alkali, and salt tolerance, making it suitable for various water pipelines, such as drainage pipes.

Thermoplastic pipes: why are they unique & how to manufacture?

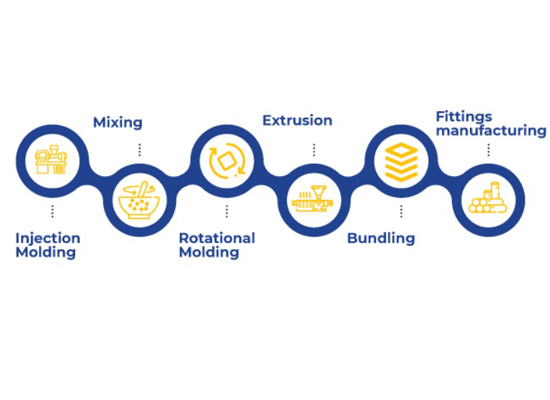

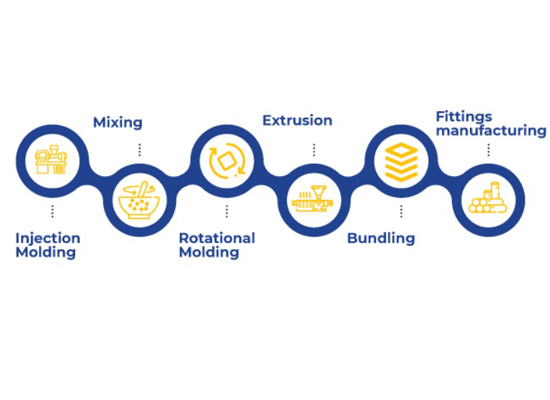

Thermoplastic plastic pipes are lightweight, non-corrosive, and cost-effective, making them an ideal alternative to metal pipes. There are many methods for manufacturing these pipes, and the following are the most common ones:

Mixing

Mix thermoplastic resin and additives in proportion; Ensure uniform physical properties of the material for subsequent processing and shaping.

Extrusion

This process is the relief of pipe forming, heating and melting the mixed plastic, and conveying it to the mold head through the extruder screw; Plastic is extruded into a continuous tubular shape in the mold

Cooling

The pipe enters the water tank or cooling device from the mold outlet, rapidly cooling and shaping; Attention should be paid to the dimensional stability of the pipes, preventing deformation, and improving surface smoothness.

Cutting

After cooling and shaping, the pipes are automatically cut according to the set length.

Bundling / Coiling

Tie the cut straight pipes into bundles, or roll the hose reel into a standard length; Labeling, plastic sealing, and packaging for easy transportation and storage.

For pipe fittings or connectors, injection molding is commonly used. Rotational molding is rarely applied due to its unsuitability for long, narrow tube shapes.

Core Characteristics of Thermoplastic Tubing

◆ Corrosion Resistance: Exhibits excellent chemical stability, resisting corrosion from various acids, alkalis, and chemical agents, making it suitable for complex working environments.

◆ Temperature and Pressure Resistance: Capable of withstanding high operating temperatures and pressures, suitable for hot and cold water supply as well as industrial pressure pipelines.

◆ Hygiene and Safety: Complies with food-grade and drinking water standards, non-toxic and odorless, ensuring the safety and hygiene of transported media.

◆ Smooth Inner Surface and Low Friction: The inner surface is smooth and polished, reducing fluid resistance, improving transport efficiency, and preventing scaling and deposits.

◆ Heat Fusion Welding and Easy Installation: Supports various heat fusion connection methods, ensuring strong sealing, and allowing for convenient and quick installation and maintenance.

◆ Long Service Life and Low Maintenance Cost: Durable materials with excellent aging resistance, offering a long service life and reducing maintenance and replacement costs.

The thermal workability of thermoplastic pipes can be reflected in the following aspects

Extrusion molding: Thermoplastic materials such as PE, PP, PVC, etc. can be transformed into a flowing state after heating, and continuously extruded into pipes through an extruder. This method is suitable for the production of large-diameter or long-distance plastic pipes, with fast molding speed and high consistency of the finished product.

Injection molding: Suitable for complex structural parts such as pipes, joints, tees, etc. made of thermoplastic materials. Its high accuracy and short cycle can meet the requirements of complex geometric shapes.

Hot bending and hot pressing: During the installation of pipes, if bending or shaping is required, the thermoplastic pipe can be heated and manually or mold shaped. After cooling, the shape can be maintained without the need for additional welding or connectors.

Another significant characteristic of thermoplastic pipes is their weldability and repairability

Hot melt docking: commonly used in PE, PPR and other pipelines, by heating two ports to melt and then docking, cooling to form a seamless connection, the joint strength is even higher than the pipe body itself.

Hot air welding: suitable for thin-walled or small-diameter pipes. The welding area is softened by a hot air gun and then fused with welding rods or base materials. It is commonly used in materials such as PVC and PP.

Convenient on-site repair: If the pipe is damaged, it can be quickly repaired on-site by cutting, replacing sections, hot welding, etc., reducing downtime and cost losses.

Comparative advantages of thermoplastic pipes and metal pipes

Cost: Due to lower raw material and production costs, as well as reduced maintenance expenses over time, thermoplastic pipes are typically more cost-effective.

Weight: much lighter than metal tubes, more flexible to use, and widely applicable in various industries.

Corrosion resistance: Unlike metal pipes, thermoplastic pipes will not rust or corrode even in harsh chemical or humid environments, effectively enhancing the service life of pipes and reducing replacement and maintenance costs.

Processing method: Thermoplastic processing is more convenient and can achieve efficient and large-scale production.

Installation efficiency: Compared with heavy-duty rigid metal pipes, thermoplastic pipes can be easily cut, connected, and installed, allowing for faster and more flexible installation.

The disadvantages of thermoplastic plastic pipes include relatively poor high-temperature resistance, making them unsuitable for prolonged exposure to elevated temperatures. Due to the nature of the material, their mechanical strength and pressure resistance are limited. Additionally, since they can be melted by heat, special caution is required when used in flammable or high-risk environments.