Feb 09, 2026

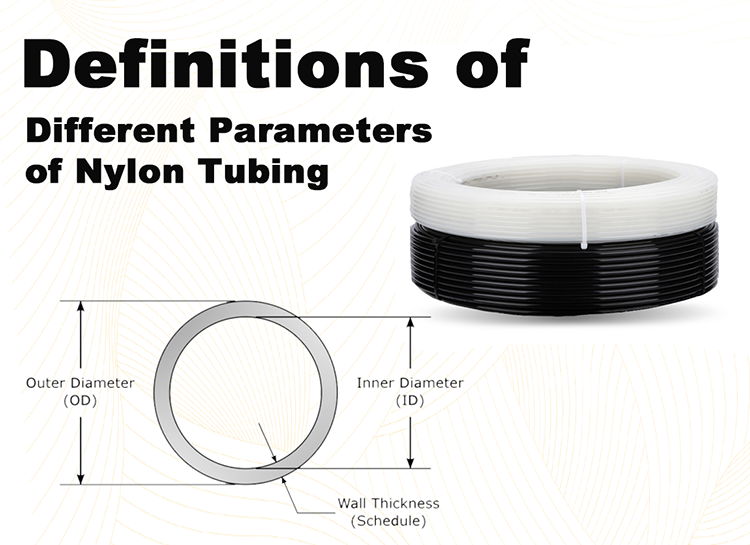

In pneumatic and fluid transfer systems, selecting the correct Nylon Tubing is not only about material type but also about structural parameters such as outer diameter (OD) and wall thickness. These dimensions directly determine the pressure capacity of a PA tubing assembly, influencing safety, service life, and system stability. Understanding how wall thickness affects pressure resistance allows engineers and distributors to choose the right Nylon hose for both standard and high-pressure installations.

The pressure resistance of Nylon air hose is primarily governed by the ratio between the outer diameter and the inner diameter. When wall thickness increases while OD remains constant, the tube gains higher structural rigidity, enabling it to withstand greater internal pressure without deformation.

In engineering practice, the simplified design logic is:

Higher wall thickness = higher allowable working pressure

However, increasing thickness also reduces flexibility and increases weight, so the selection must balance pressure requirement and installation conditions.

While exact pressure ratings should follow manufacturer testing standards, engineers often use proportional comparison when selecting a PA tube with the same material grade. If two tubes share identical material (PA6, PA66, or PA12) and OD, the thicker version typically supports a proportionally higher pressure range.

For example, under identical material conditions:

| OD (mm) | Wall Thickness (mm) | Relative Pressure Capacity |

|---|---|---|

| 8 | 1.0 | Standard duty |

| 8 | 1.5 | Medium pressure |

| 8 | 2.0 | High pressure |

This comparison method is widely used during preliminary equipment design before confirming final pressure ratings from supplier technical data sheets.

Wall thickness is not the only factor affecting performance. Different materials used in Nylon Tubing provide different mechanical strengths even at the same dimensions.

1.PA12 tubing offers excellent flexibility and stable pressure performance in low-temperature environments.

2.PA66 tubing provides higher rigidity and better strength at elevated temperatures.

3.PA6 tubing delivers a cost-efficient balance suitable for general industrial air systems.

Therefore, when evaluating pressure capability, engineers typically first select the material grade and then adjust wall thickness to match the required safety margin.

In practical automation equipment design, engineers often follow a three-step approach when selecting Nylon hose:

1.Determine system working pressure and safety factor

2.Select suitable material (PA6, PA66, or PA12) based on environment

3.Increase wall thickness if higher pressure resistance is required

For compact equipment installations where bending flexibility is important, moderate thickness tubing is preferred. In contrast, high-pressure distribution lines typically use thicker-wall PA tubing to ensure long-term reliability.

In automated production lines, air distribution manifolds frequently use 8–12 mm OD Nylon air hose. When system pressure increases from 8 bar to 12 bar, engineers often upgrade wall thickness rather than changing tube diameter, allowing the system layout and connectors to remain unchanged while improving pressure tolerance.

Manufacturers offering multiple thickness options enable distributors and OEM designers to match performance precisely to the application without redesigning the entire piping layout.

When comparing tubing specifications, always review three parameters together: material grade, outer diameter, and wall thickness. Among these, wall thickness is the fastest adjustable parameter for increasing pressure capacity, making it a key decision factor for procurement managers and equipment designers working with compressed-air or fluid transfer systems.

Selecting the correct thickness not only improves safety margins but also reduces the risk of deformation, leakage, and premature tubing replacement in demanding industrial environments.

(FK9026)

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

M5 and 4mm Selection Logic for Mini Type Pneumatic Push In Fittings in Micro Equipment

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Polyurethane Tube Hardness and Its Influence on Pneumatic System Response Speed

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

Drag Chain Polyurethane Tube: Why 95A and 98A PU Tubing Perform Better in Automation Systems

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

PVC Flexible Tubing in Vacuum Systems: Preventing Collapse and Flow Loss

Nylon Tubing Materials: Is PA66 Stronger Than PA6

Nylon Tubing Materials: Is PA66 Stronger Than PA6

You May Interest In

May 07, 2025 Blog

Comprehensive Analysis of Pneumatic Push in Fittings

Apr 22, 2025 Blog

Solution for Nylon Tube

Apr 16, 2025 Blog

PVC Tubing vs. Polyurethane Tubing

Apr 10, 2025 Blog

What is the difference between pu and pvc

Feb 24, 2025 Blog

How to Identify Hydraulic Quick Couplers?

Jan 21, 2025 Blog

How to Measure Pipe Thread?

Jan 16, 2025 Blog

What Is Pipe thread?

Dec 04, 2024 Blog

Application Of Tube Fitting

Jun 26, 2023 Blog

What Is The Difference Between LLDPE And LDPE?

Jan 17, 2023 Blog

What Are The Classification Of Plastics?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap