Feb 05, 2026

Pneumatic systems rely on small components to keep the entire production line stable, and Pneumatic Quick Coupling is one of the most critical. Failures of pneumatic fittings, often lead to air leakage, pressure loss, and unexpected downtime. Many of these problems are not caused by poor product quality but by unsuitable material selection and lack of daily protection. Understanding how water, oil mist, UV light, chemicals, and temperature affect fittings helps engineers and distributors provide more reliable solutions to end users.

In factories such as food packaging, welding equipment, or automated assembly, push-to-connect fittings are exposed to complex environments. Moisture in compressed air can corrode metal parts, while oil vapor may swell sealing rings. Dust entering the locking mechanism of one-touch fittings gradually reduces gripping force on the tube. High temperature near molding machines hardens plastic bodies, and UV light in outdoor equipment accelerates aging. Even a high-quality tube fitting can lose performance if the material does not match the media and temperature range. Selecting brass, stainless steel, or engineering plastic according to the medium is the first step of preventive maintenance.

Many distributors overlook the period between delivery and installation. Air fittings should be stored away from direct sunlight and packed in clean plastic bags to avoid dust. Mixing different models in one box may damage the release sleeve or sealing surface. For projects with long construction cycles, periodic inspection is necessary to ensure that O-rings remain elastic. Good storage practice costs almost nothing but significantly extends the service life of push-in connectors once they are put into operation.

Before mounting any pneumatic quick coupling, check the threads of both the fitting and the mating component. Burrs or deformation will cut the seal and cause micro leakage. When wrapping PTFE tape, avoid excessive layers, which may crack the body during tightening. Tube preparation is equally important. Flexible hose must be inserted without bending stress, and the end face should be square. For rigid nylon or PU tubes, a small chamfer helps the collet of push-in fittings grip evenly and prevents scratching the sealing ring.

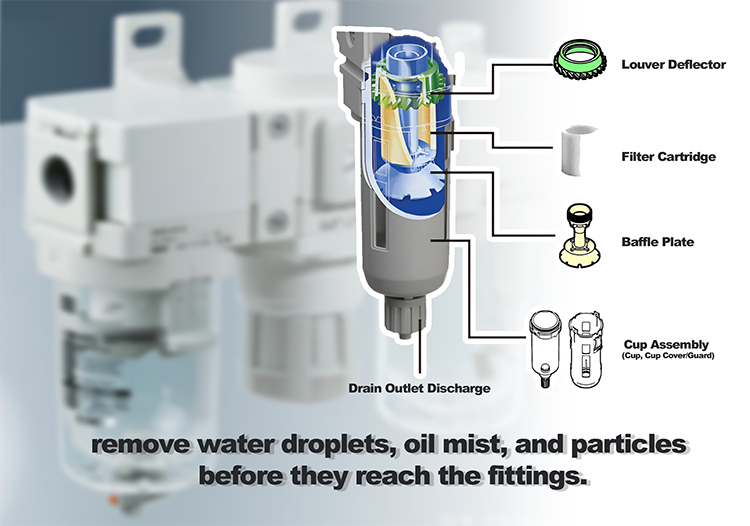

The quality of compressed air determines the lifetime of the entire circuit. Installing a filter-regulator-lubricator unit upstream can remove water droplets, oil mist, and particles before they reach the one-touch fittings. Pressure should be adjusted within the recommended range instead of running the system at the maximum limit. Sudden pressure surges are a common hidden killer of tube fittings, especially in long pipelines.

| Risk factor | Possible damage to fittings | Practical prevention |

|---|---|---|

| Water in air | Corrosion, seal swelling | Install air dryer and filter |

| Oil vapor | Deformation of O-rings | Choose oil-resistant material |

| UV exposure | Aging of plastic body | Use protective cover or metal type |

| Dust | Collet jamming | Keep packaging sealed, add filter |

| High temperature | Loss of strength | Select stainless or high-temp resin |

Technicians do not need complicated tools to evaluate pneumatic fittings. Listen for slight hissing, check whether the tube can rotate freely after insertion, and confirm that the release sleeve returns smoothly. Any sign of discoloration or cracking means the material has been attacked by chemicals or heat. Replacing a single push-to-connect fitting early is far cheaper than repairing a whole machine after leakage contaminates sensors or valves.

For distributors and purchasing managers, offering guidance on maintenance differentiates your brand from competitors who only sell parts. Equipment engineers benefit from fewer stoppages and stable pressure at actuators. End users gain lower energy consumption because well-maintained air fittings prevent continuous air loss. Preventive thinking turns a simple component into a long-term guarantee for system reliability.

Careful material selection, correct installation, and clean air supply form a complete protection chain for Pneumatic Quick Coupling. When these steps become routine, the service life of push-in fittings can be multiplied, helping factories run smoothly and allowing partners in the supply chain to build lasting trust with their customers.

(FK9026)

How to Judge the Quality of Polyurethane Tubing

How to Judge the Quality of Polyurethane Tubing

How to Extend the Life of Pneumatic Quick Coupling through Preventive Maintenance

How to Extend the Life of Pneumatic Quick Coupling through Preventive Maintenance

Hidden Impacts of Excessive Exhaust Noise in Pneumatic Systems

Hidden Impacts of Excessive Exhaust Noise in Pneumatic Systems

Carbon Steel Connector Load Capacity Advantages in High-Pressure Pneumatic Systems

Carbon Steel Connector Load Capacity Advantages in High-Pressure Pneumatic Systems

Hand Valve Installation Direction Errors and Their Impact on Pneumatic Systems

Hand Valve Installation Direction Errors and Their Impact on Pneumatic Systems

You May Interest In

May 07, 2025 Blog

Comprehensive Analysis of Pneumatic Push in Fittings

Apr 22, 2025 Blog

Solution for Nylon Tube

Apr 16, 2025 Blog

PVC Tubing vs. Polyurethane Tubing

Apr 10, 2025 Blog

What is the difference between pu and pvc

Feb 24, 2025 Blog

How to Identify Hydraulic Quick Couplers?

Jan 21, 2025 Blog

How to Measure Pipe Thread?

Jan 16, 2025 Blog

What Is Pipe thread?

Dec 04, 2024 Blog

Application Of Tube Fitting

Jun 26, 2023 Blog

What Is The Difference Between LLDPE And LDPE?

Jan 17, 2023 Blog

What Are The Classification Of Plastics?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap