What is Polyolefin Tubing

Polyolefin tubing is a type of extruded plastic tube that shrinks in diameter when exposed to heat. Polyolefin is the most commonly used material for manufacturing heat shrink tubing due to its flexibility, resilience, and high resistance to environmental stress.

Polyolefin heat shrink tubing, made from polyolefin as the base material, is a cross-linked modified polymer. Due to its thermal shrinkage, Polyolefin pipe can also be referred to as Polyolefin heat shrinkable tubing. After heating, it will shrink to 1/2 or 1/3 of its original diameter, tightly adhering to the coating.After cooling, polyolefins are formed protective layer that provides electrical insultation and strain relief, prevents moisture ingress, and aids in identification.

Features and Funtions of Polyolefin shrinkable Tubing

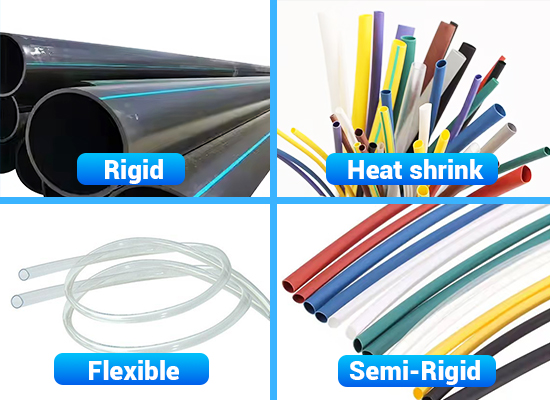

Polyolefin shrink tubing is widely used. Due to varying demands for its flame retardancy and heat shrinkable behavior, Polyolefin hose is often categorized based on the following four typical and practical characteristic types: rigid, semi-rigid,flexible, and heat shrink.

Polyolefin tubing has different pipe types includ LDPE, LLDPE, PP,Ethylene Vinyl Acetate Copolymer can indeed be classified as rigid, semi-rigid, or flexible based on their physical properties.

Other properties available from polyolefin pipes

Remove heat shrink properties, the performance of polyolefin heat shrink tubing properties can be enhanced by adding relevant agents, depending on the application.

Flame retardants:With the addition of such modifying agents, the pipe exhibits a slower burning rate or self-extinguishes when exposed to a flame.

UV stabilizers:With the addition of such modifying agents, the pipe can be used outdoors for extended periods without significant aging.

Plasticizers:With the addition of such modifying agents, the pipe exhibits greater flexibility and is less prone to cracking in low-temperature environments.

Antistatic agents:With the addition of such modifying agents, the pipe’s surface resistivity is reduced, making it less prone to static charge accumulation.

Types of Polyolefin tubing

Polyolefin tubes can be categorized into various types through the addition of additives and adjustment of dimensional specifications. Let's explore three kinds mechanical properties.

Rigid Polyolefin tube type

Characteristics

This kind shrink polyolefin tube has High hardness, fixed shape, not easy to bend commonly was applied in Architecture and Infrastructure,Pipeline system manufacturing.

Semi-rigid Polyolefin heat shrink tube type

Characteristics

This kind polyolefin pipe combines a certain degree of structural strength with flexibility, offering greater adaptability and a wider range of applications.

Application

automotive industry

EADS

Electrical Engineering

Industrial Automation

Flexible Polyolefin tube type

Characteristics

Polyolefin flexible tube has the best heat-shrinkability and features soft and easy to bend and Cross-linking can enhance its temperature resistance, durability, and other properties.Flexible polyolefin shrinkable tubine is very suitable for applications requiring bending or movement as follows.

Application

Medical equipment manufacturing

Food and Beverage Industry

Laboratory equipment

These three common mechanical properties types that make the application and industry more extensive range of Polyolefin heat shrink Tubing.PVC tubing famliy also has a common type of heat shrink plastic tubing. How does its heat shrinkability compare to polyolefin tubing?Browse this article for more content.

Application of Polyolefin Tubing

Polyolefin heat shrink tubing is mainly used in the following industrial sectors according to its Excellent heat and weather resistance, chemical resistance, electrical insulation, and non-toxic, environmentally friendly properties.

◆ Electronics and Electrical Industry

◆ automotive industry

◆ Industrial Automation

◆ Energy and Petrochemical Industry

◆ medical equipment

◆ Architecture and Infrastructure

The heat-shrinkable properties of polyolefin tubing are primarily used for electrical insulation, mechanical protection, sealing against moisture, and cable management. It is applicable across most industrial and electronics-related sectors.

Performance Characteristics of Different Types of Polyolefin Tubing

◆ PE Polyethylene Tube

PE (Polyethylene) Tube is a versatile and lightweight polyolefin tubing material known for its excellent chemical resistance and durability. It is commonly used in fluid transfer applications for water, air, and other non-aggressive fluids.

PE tubing is flexible, easy to install, and offers good impact resistance, making it ideal for industries like agriculture, construction, and automation. Available in various sizes,

PE tubes are an economical choice for both low-pressure and medium-pressure systems.

◆ LDPE Low Density Polyethylene Pipe

Low-density polyethylene,a very typical type of polyolefin material,also known as high-pressure polyethylene (LDPE), is the lightest variety of polyethylene resin, appearing as milky white, tasteless, odorless, non-toxic, and non-glossy waxy particles.

It possesses good flexibility, elongation, electrical insulation, transparency, processability, and some degree of breathability. It exhibits relatively good chemical stability, being resistant to alkalis and general organic solvents.

◆ LLDPE Linear Low Density Polyethylene Pipe

Linear low-density polyethylene (LLDPE) is formed by copolymerizing ethylene with a small amount of α-olefin, resulting in a molecular structure with very short copolymer monomer side chains attached to the linear ethylene main chain.

Linear low-density polyethylene is a milky white granule that is non-toxic, tasteless, and odorless, with a density ranging from 0.918 to 0.935g/cm3.

Compared to LDPE tubing, it has a higher softening temperature and melting temperature, with advantages such as greater strength, good toughness, rigidity, heat resistance, and cold resistance. It also exhibits good environmental stress cracking resistance, impact strength, tear strength, and resistance to acids, alkalis, organic solvents, etc., making it widely used in industrial, agricultural, medical, sanitary, and daily life products.

◆ PP Polypropylene Tube

PP polypropylene has a lower heat deformation temperature (100°C), low transparency, low glossiness, and low rigidity, but it has stronger impact resistance. The impact strength of PP increases with the increase of ethylene content. The Vicat softening temperature of PP is 150°C. Due to its high crystallinity, this material exhibits good surface stiffness and scratch resistance.

Polypropylene tubing is non-toxic, corrosion-resistant, non-scaling, heat-resistant, and corrosion-resistant, with smooth inner walls and lightweight. They are mainly used in urban water supply, chemical industry, petroleum, chlor-alkali, pharmaceuticals, dyes, pesticides, food, metallurgy, electroplating, environmental protection, water treatment, and other industries.

◆ EVA Ethylene Vinyl Acetate Copolymer

EVA is an elastic polymer that can produce materials with softness and flexibility similar to rubber. This material exhibits good transparency, glossiness, low-temperature toughness, stress-crack resistance, hot-melt adhesive waterproof performance, and resistance to ultraviolet radiation.

EVA has a distinctive vinegar-like odor and can compete with rubber and ethylene-based polymer products in many electrical applications. It is often used in the production of footwear, packaging materials, industrial products, medical devices, household items, sports equipment, and more.

Quality and Service

Fokca is one of polyolefin heat shrink tubing manufacturers in china and focus on "Focus on keeping customers ahead"keeping our customers ahead. We utilize high-quality raw materials and advanced, reliable manufacture technology.

Whether you require special customized polyolefin tubing sizes and specifications, brand customization, or solutions for specific application scenarios, Fokca can meet your individual needs. Choosing Fokca means not only selecting excellent quality but also choosing reliable performance, offering assurance and peace of mind.For more information on polyolefin tubing, please do not hesitate to Contact us.