EVA Ethylene Vinyl Acetate copolymer is a versatile material known for its flexibility, durability, and excellent impact resistance. It combines the properties of both ethylene and vinyl acetate, offering a balance of strength, elasticity, and toughness.

EVA is resistant to UV radiation, stress cracking, and moisture, making it suitable for use in a wide range of applications, including packaging, automotive, medical devices, and footwear. It is also commonly used in the production of flexible tubing, as it maintains its shape and performance under various environmental conditions.

Ethyl-vinyl acetate thermoplastic copolymer (EVA) is a fusion of ethylene and vinyl acetate. Its diverse benefits include excellent softness, elasticity, processability, and transparency make EVA a material between plastic and rubber.

Ethyl vinyl acetate copolymer has diverse thermal properties, making it versatile uses particularly suitable for industries requiring high flexibility, transparency, and environmental safety, including medical devices, packaging, and photovoltaic cables.Our article mainly introduces its thermoplasticity, adjustable low melting point, thermal adhesion and other thermal properties.

In addition to thermal properties,eva ethylene vinyl acetate copolymer also has some other material properties that we will explore together.

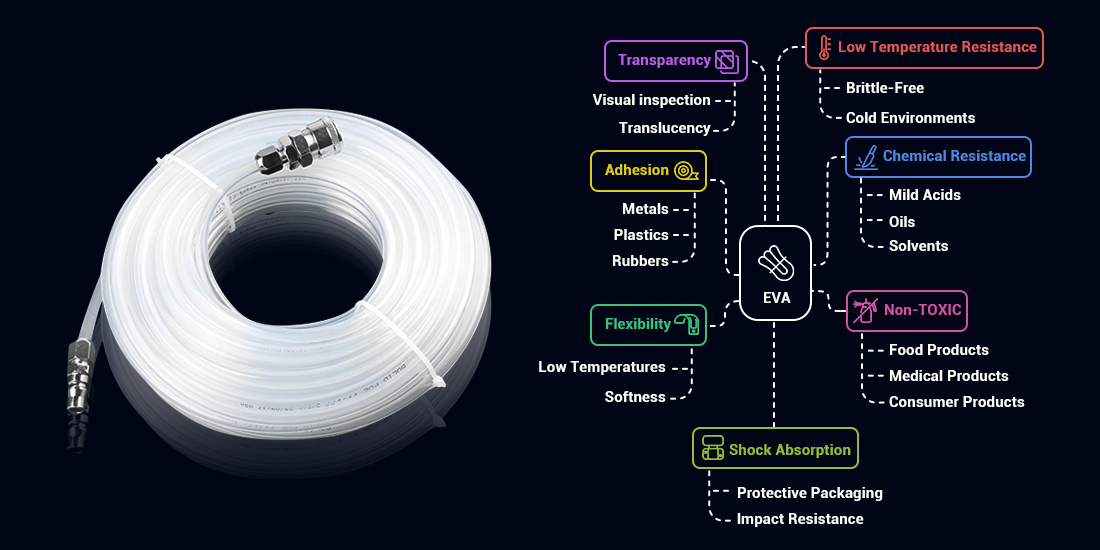

◆ Flexibility:

EVA offers excellent flexibility, even in low temperatures, making it ideal for applications requiring soft, bendable materials.

◆ Transparency:

It is often transparent or translucent, allowing for easy visual inspection of contents or flow.

◆ Good Adhesion:

Provides strong adhesion to other materials like metals, plastics, and rubbers.

◆ Chemical Resistance:

Resistant to mild acids, oils, and solvents, though it is less resistant to strong chemicals compared to other materials.

◆ Low Temperature Resistance:

Performs well in low-temperature environments without becoming brittle.

◆ Shock Absorption:

Offers good cushioning properties, making it suitable for protective packaging and impact-resistant applications.

◆ Non-Toxic and Safe:

Generally copolymer considered non-toxic, making it safe for use in food, medical, and consumer products.

For more detail you can contact us.

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap