Introduce

With the widespread adoption of automation equipment, the demand for highly flexible, wear-resistant, and pressure-resistant hose tubing has grown rapidly in modern industries. Polyurethane tubing is becoming increasingly important in modern industrial applications include Pneumatics and Automationm,Medical,Food and Beverage and Electronics and Electrical industries.

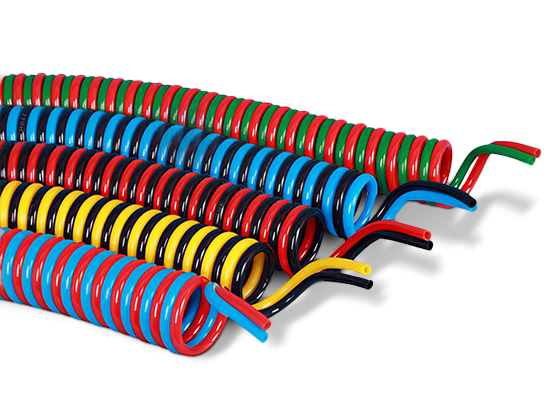

Polyurethane tubing is easy to cut, with smooth inner walls and low flow resistance, making it very suitable for long-distance fluid transmission. The spiral structure of polyurethane coiled tubing, on the other hand, is more suitable for use with air guns and pneumatic screwdrivers in limited spaces.

What is Polyurethane Tubing ?

Characteristics and Advantages Of Polyurethane Tubing

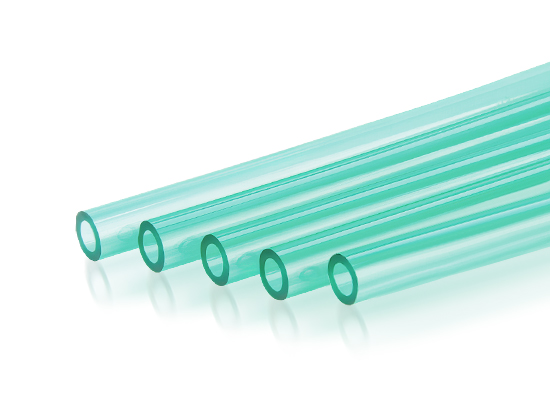

Polyurethane tubing is resistant to oil, aging, and has high hardness and elasticity. Polyurethane tube exhibits high tear strength, heat resistance, and excellent transparency, along with good tensile, flexural, abrasion resistance, and solvent resistance. It is not easily oxidized and achieves a level of 3 or above in resistance to yellowing.

◆ Elasticity and Flexibility: PU tube possesses excellent elasticity and flexibility, making it suitable for curved and bent applications. It can undergo stretching and bending without losing its elasticity.

◆ Wear Resistance: The most obvious advantage of Polyurethane tubing typically has high wear resistance, making it suitable for applications that involve frequent movement or bending.

◆ Automatic rebound: The spiral polyurethane tube can automatically shrink when not in use, taking up no space and making it very convenient for recycling and wiring.

◆ Chemical Corrosion Resistance: PU tubing shows resistance to certain chemicals, although the specific corrosion resistance may vary depending on material preparation.

◆ Excellent Air Tightness: PU tube generally has good airtightness, making it suitable for applications involving gas transmission, such as pneumatic systems.

◆ High-Temperature and Low-Temperature Resistance: PU tube can maintain elasticity and flexibility within a certain temperature range, making it suitable for both high and low-temperature environments.

◆ Lightweight: Polyurethane tubing is relatively lightweight, making it easy to handle and install.

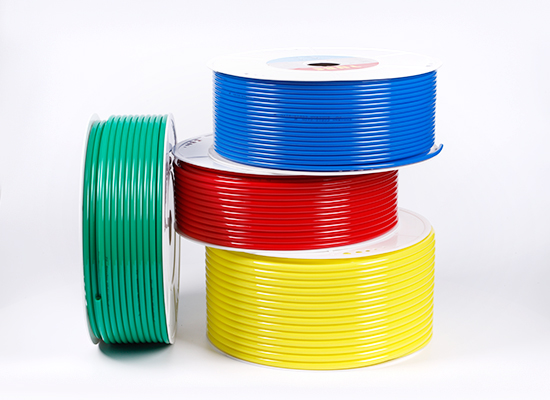

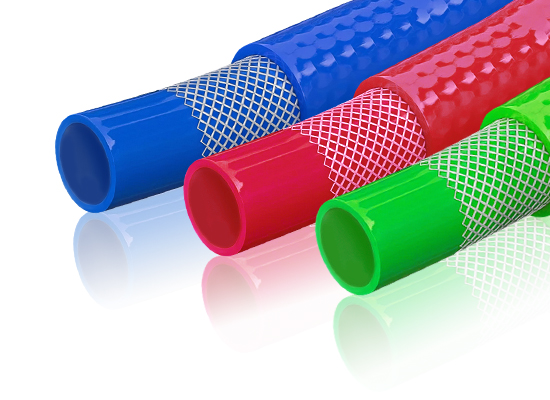

◆ Diverse Colors: With over 30 color options available, PU tube can be customized based on application requirements, aiding in distinguishing different pipeline uses.

◆ Environmental Friendliness: Polyurethane material is considered a relatively environmentally friendly choice in some applications, especially when compared to certain other plastic materials.

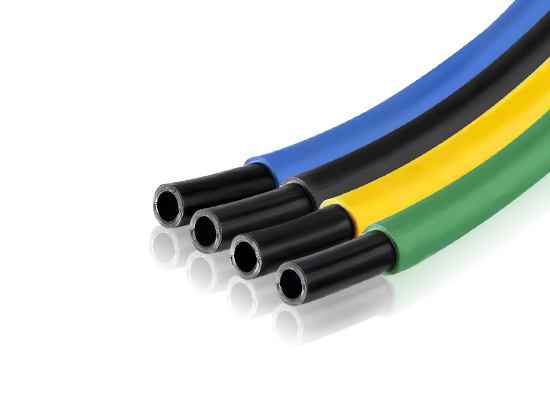

Types of Polyurethane Tubing

Polyurethane pipe is a representative flex tube pu hose made of polyurethane material, characterized by its transparent body.PU tube is widely used in various industries due to their excellent flexibility, durability, and resistance to abrasion.

Among these, the polyurethane tube stands out as a specialized type designed specifically for compressed air and pneumatic applications, offering superior performance in high-pressure environments.

Standard Polyurethane Tubing :For general industrial use, standard polyurethane hose is suitable for general pneumatic systems to serve as fluid transportation.Polyester based PU belongs to a standard Polyurethane Tubing type.

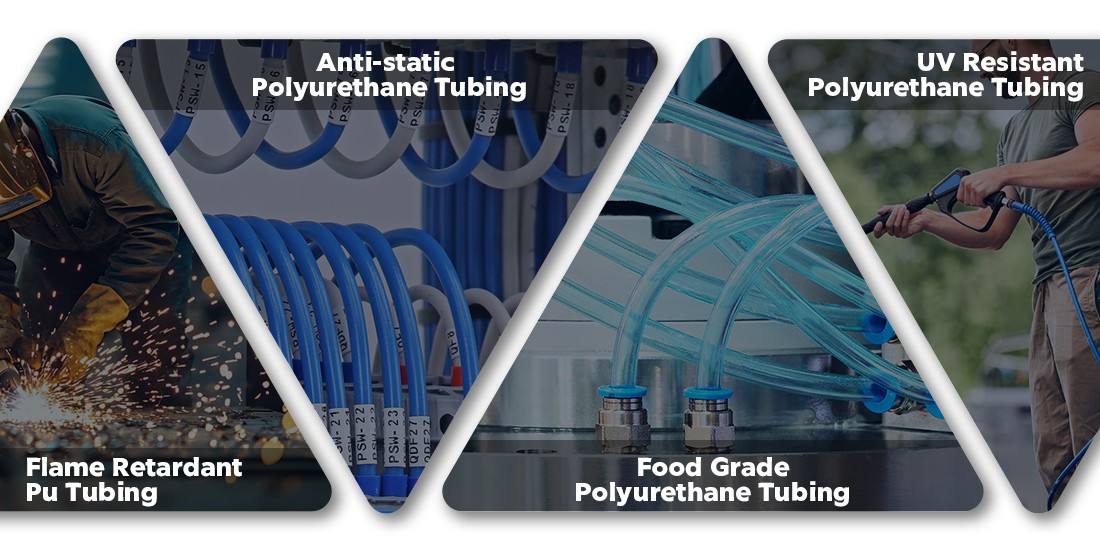

UV Resistant Polyurethane Tubing:UV resistance polyurethane tubing, very suitable for outdoor or direct sunlight environments.

Flame Retardant PU Tubing:Having certain fire and flame retardant properties, polyurethane tubing is used in occasions that require fire prevention, such as rail transit and electronic manufacturing.

Food Grade Polyurethane Tubing:Made of non-toxic materials that meet food hygiene standards, it can be used in the food or beverage industry.

Anti-static Polyurethane Tubing:This type of pu tube suits for preventing static electricity accumulation in electronic and dusty environments.

Fokcaflow manufacture various types of polyurethane tubing includes pu tube 6mm,10mm,12mm,While ensuring product quality, also offer highly competitive pu tube price.

Application of Polyurethane Tubing

◆ Pneumatic Systems

◆ Medical and Laboratory Equipment

◆ Packaging and Food Machinery

◆ Automotive Industry

◆ Textile and Printing Industry

Parameters of Polyurethane Tubing

Polyurethane pipe has the characteristics of wear resistance, oil resistance, aging resistance and low cost for long-term use, fully understanding their parameters can give full play to their advantages:

| Raw material | Thermoplastic Polyurethane |

| Applicable medium | Air, Water, Vacuum |

| Working pressure | 0~0.8MPa |

| Max.applicable pressure | 1.0MPa |

| Burst pressure | 2.5MPa |

| Embient and fluid temperature | -20℃~+60℃ |

| Hardness Shore A | 80A~98A ASTM D-2240 |

| Tensile strength(kg/cm2) | 600 ASTM D-638 |

| Ultimate elongation(%) | 490~590 ASTM D-638 |

| Taber abrasion(mg) | 30~40 ASTM D-1044 |

| Tear strength(kg/cm2) | 155 ASTM D-732 |

Quality and Reliability

Fokcaflow manufactures polyurethane tubing by using high-quality raw materials, strictly adhering to quality standards to ensure excellent performance in various environments. Employing advanced and reliable processes, our carefully designed production ensures each polyurethane pipe undergoes rigorous testing, guaranteeing it meets or exceeds industry standards.

This comprehensive quality control spans the entire production process, reflecting our commitment to reliability from procurement to the final product.

Choosing Fokca's polyurethane tube means opting for not only outstanding quality but also reliable performance. We integrate innovative technologies in both product design and manufacturing, emphasizing strict quality control at every stage.

This ensures our polyurethane tubing perform stably and reliably in demanding industrial environments and other complex scenarios. Customers can confidently choose our products, enjoying the practical value of exceptional performance and enduring quality.

Technical Support and Services

Fokcaflow is not only a manufacturer to supply top-notch polyurethane tubing,but is also committed to providing personalized technical pneumatic tubing for your pneumatic system. We can customize the appearance, color, shape, working pressure, working temperature, working environment, and hardness of our PU tubes based on your needs.

Additionally, customized packaging services are available. Whether it's a unique design, branding requirements, or specific application needs, Fokcaflow can meet your personalized requirements. We believe that through customization, we can provide you with Polyurethane Tubing solutions that perfectly match your operational needs.

If you have any requirements or questions,please feel free to Contact us.